Concrete End Hose Pipe :

Concrete End Hose Pipe - An essential component in construction, a concrete end hose pipe facilitates the precise and efficient transfer of concrete from the pump to the intended surface. Constructed with robust materials, it ensures a reliable flow of concrete while withstanding pressure and abrasion. This flexible tool is vital for reaching challenging areas and maintaining a continuous concrete placement process. Its durability and adaptability make it indispensable in various construction projects, from buildings to infrastructure. The concrete end hose pipe streamlines the concrete placement process, enhancing project efficiency and contributing to the creation of sturdy structures.

Introduction to Concreate End Hose Pipe

A concrete end hose pipe, also known simply as an end hose or end hose pipe, is a specialized component used in concrete pumping equipment. Concrete pumps are used to transfer liquid concrete from a mixer truck or hopper to the intended construction site, often at a significant distance or height. The end hose pipe is a crucial part of this pumping system as it serves as the final conduit through which the concrete is delivered to its destination.

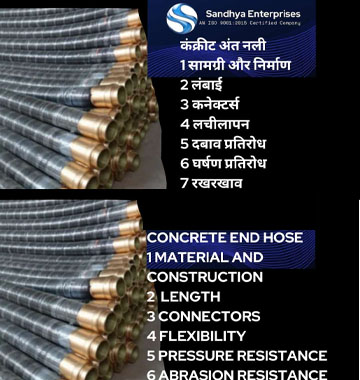

Key features and functions of a concrete end hose pipe include:

- **Material Composition:** End hose pipes are typically constructed from highly durable materials to withstand the abrasive nature of concrete and the high pressure exerted during pumping. They are often reinforced with multiple layers of high-strength steel wires for added durability and flexibility.

- **Length and Diameter:** End hose pipes come in various lengths and diameters to accommodate different pumping requirements. The length of the hose determines how far the concrete can be pumped, while the diameter influences the flow rate and pressure capabilities.

- **Flexibility:** The hose needs to be flexible enough to navigate around obstacles and reach the desired pouring location. This flexibility allows it to snake through complex construction sites without compromising the integrity of the hose or the concrete being pumped.

- **End Fittings:** The end fittings of the hose are designed to securely attach to the concrete pump's outlet and the nozzle at the delivery point. These fittings ensure a tight connection, preventing any leakage of concrete during the pumping process.

- **Abrasion Resistance:** Since concrete contains coarse aggregates, it can be abrasive to the hose over time. Quality end hose pipes are designed to withstand this abrasion and maintain their structural integrity even after prolonged use.

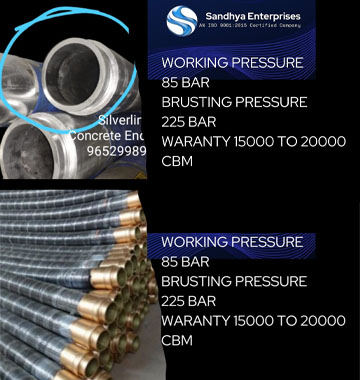

- **Pressure Rating:** Concrete pumps exert significant pressure to propel the concrete through the hose to its destination. End hose pipes are designed to handle these high pressures without rupturing or leaking.

- **Safety Measures:** Operators and workers need to follow safety guidelines when working with concrete pumping equipment. Proper training and precautions are necessary to prevent accidents and ensure the efficient and safe operation of the equipment.

- **Maintenance:** Regular maintenance and inspection of the end hose pipe are essential to identify any signs of wear, damage, or fatigue. Damaged hoses should be replaced promptly to prevent unexpected failures during concrete pumping.

Concrete end hose pipes play a critical role in the construction industry by enabling the efficient and precise placement of concrete in hard-to-reach or elevated areas. They are commonly used in various construction projects, including building construction, infrastructure development, and more.

It's important to note that technology and equipment specifications can evolve, so it's always recommended to refer to the manufacturer's guidelines and industry best practices for the most up-to-date information on concrete end hose pipes and their usage.

Components of a Concreate End Hose Pipe

A concrete end hose pipe is composed of several key components that work together to facilitate the transfer of concrete from the pump to the desired pouring location. These components ensure the durability, flexibility, and safety of the hose during the pumping process. The specific design and materials of these components may vary based on the manufacturer and the intended application. Here are the main components of a concrete end hose pipe:

- **Inner Tube:** The inner tube is the innermost layer of the hose and comes into direct contact with the concrete being pumped. It is typically made of synthetic rubber that is resistant to the abrasive nature of concrete and can handle the pressure of the pumping process.

- **Reinforcement Layer:** The reinforcement layer consists of multiple layers of high-strength steel wire braids or spirals. These layers provide structural integrity to the hose, enabling it to withstand the high pressures and maintain its shape while under stress.

- **Cover:** The outer cover of the hose acts as a protective layer against external elements such as sunlight, abrasion, and physical damage. It is usually made from synthetic rubber or a combination of rubber and other materials. The cover also contributes to the overall flexibility of the hose.

- **End Fittings:** The end fittings are metal connectors located at each end of the hose. They are designed to securely attach the hose to the concrete pump's outlet and the delivery nozzle. These fittings are crucial to ensure a tight connection that prevents concrete leakage during the pumping process.

- **Flanges:** Flanges are flat, disc-like components attached to the end fittings. They provide a stable platform for connecting the hose to the pump and nozzle. Flanges are usually made of steel and are bolted together to create a secure connection.

- **Bend Restrictors:** Bend restrictors are added to the hose at various points to prevent excessive bending, kinking, and wear. They are often made of rubber or plastic and are strategically placed to protect the hose from damage where it is likely to bend or rub against surfaces.

- **Anti-Whip Devices:** Anti-whip devices are safety mechanisms installed at the end of the hose to control any sudden movements or "whipping" of the hose if it were to detach unexpectedly. These devices help prevent accidents and injuries on the construction site.

- **Identification Markings:** Many hoses have identification markings that provide information about the manufacturer, specifications, pressure ratings, and other relevant details. These markings help ensure that the hose is used appropriately and safely.

- **Pressure Rating Labels:** Pressure rating labels are affixed to the hose to indicate the maximum pressure the hose can handle. This information is essential for operators to ensure that the hose is used within its specified limits.

- **Safety Cables:** Safety cables are sometimes attached to the hose as an additional safety measure. They provide an extra layer of security by preventing the hose from flailing excessively in case of a failure.

These components work in harmony to create a robust and reliable concrete end hose pipe, allowing for the efficient and safe pumping of concrete in construction projects. It's important to note that the quality and design of these components greatly influence the overall performance and lifespan of the hose. Regular inspection, maintenance, and adherence to manufacturer guidelines are crucial for safe and effective operation.

Working Principle

The working principle of a concrete end hose pipe is closely tied to the operation of a concrete pump and its ability to transfer concrete from a mixing source (such as a truck-mounted mixer) to a specific location on a construction site. The end hose pipe is the final link in this process, responsible for delivering the concrete mixture to its intended destination.

Here's how the working principle of a concrete end hose pipe generally unfolds:

- **Concrete Pumping System Setup:** A concrete pump consists of a hopper where the fresh concrete mixture is loaded and a hydraulic system that provides the necessary power to move the concrete. The pump system is connected to the mixing truck or a separate mixer, and the concrete is pushed or pulled through the pump's internal mechanism.

- **Concrete Transfer to the Pump:** The concrete mixture is transported from the mixing source into the pump's hopper. The pump's hydraulic system creates pressure, which is used to move the concrete through the pump's internal components.

- **Pressurized Transfer:** The hydraulic system generates pressure that forces the concrete through a series of pipes and hoses. As the concrete moves through these components, its flow is maintained, and pressure is regulated to ensure a continuous and controlled delivery.

- **Transition to the End Hose Pipe:** As the concrete reaches the end of the pump's delivery line, it enters the concrete end hose pipe. This hose is designed to handle the high pressure and abrasive nature of the concrete mixture.

- **Concrete Delivery:** The end hose pipe is flexible and can be maneuvered to the desired pouring location, whether it's a remote area, elevated surface, or any other challenging location. The operator uses the end hose pipe to guide the flow of concrete to where it's needed.

- **Precision Pouring:** The operator at the end of the hose pipe directs the concrete's flow with precision, ensuring that it's evenly distributed and properly placed. The flexibility of the hose allows for accurate pouring even in complex construction scenarios.

- **Completion of Pouring:** Once the desired amount of concrete has been pumped and poured, the operator closes off the flow. The end hose pipe can be detached from the delivery nozzle, and the pump can be prepared for the next pour if necessary.

- **Safety Measures:** Throughout the entire process, safety measures are paramount. Operators need to be trained in the proper use of the equipment to prevent accidents, and safety devices like anti-whip systems are in place to mitigate risks associated with hose detachment or sudden hose movements.

In summary, the concrete end hose pipe acts as the final conduit for delivering concrete from the pump to the construction site. It facilitates the precise placement of concrete, making it possible to reach areas that would be difficult to access using traditional pouring methods. The key to successful and safe operation lies in the coordination of the pump's hydraulic system, the manipulation of the end hose pipe by skilled operators, and the appropriate maintenance of all components involved.

Advantage of Using a Concreate End Hose Pipe

Using a concrete end hose pipe offers several advantages in the context of concrete pumping and construction projects. Here are some of the key advantages:

- **Precise Placement:** Concrete end hose pipes allow for accurate and targeted placement of concrete. This precision is essential when pouring concrete in specific locations, such as hard-to-reach areas, elevated surfaces, or confined spaces.

- **Flexibility:** The flexibility of the hose enables it to navigate around obstacles, making it suitable for complex construction sites where rigid pipes might be impractical. This flexibility allows for greater versatility in concrete pouring.

- **Increased Reach:** End hose pipes can extend over significant distances, enabling concrete to be pumped to areas that are far away from the source of the concrete. This increased reach reduces the need for manual labor to transport concrete and minimizes disruptions to the construction site.

- **Elevated Pouring:** When working on multi-story structures, such as high-rise buildings, end hose pipes are essential for pumping concrete to elevated locations. They eliminate the need for manual labor to carry concrete up ladders or scaffolding.

- **Time and Labor Savings:** Concrete end hose pipes accelerate the pouring process by reducing the time required for manual transportation of concrete to different parts of the construction site. This leads to increased efficiency and productivity.

- **Reduced Material Waste:** The controlled delivery of concrete through the end hose pipe reduces the likelihood of spills or waste, contributing to cost savings and a cleaner work environment.

- **Improved Safety:** Concrete pumping with end hose pipes reduces the physical strain on workers who would otherwise have to manually transport heavy concrete loads. It also minimizes the risks associated with carrying heavy loads and working at heights.

- **Consistent Concrete Quality:** The controlled and continuous flow of concrete through the end hose pipe helps maintain consistent concrete quality. This is crucial for achieving the desired structural integrity and finish of the final construction.

- **Cost Efficiency:** While there's an initial investment in concrete pumping equipment, the time saved, reduced labor costs, and increased project efficiency can lead to overall cost savings in the long run.

- **Versatility:** Concrete end hose pipes are compatible with various types of concrete pumps, making them adaptable to different construction projects and equipment setups.

- **Reduced Environmental Impact:** Concrete pumping with end hose pipes can help reduce the carbon footprint of construction projects by minimizing the need for heavy machinery and reducing the use of manual labor.

- **Access to Challenging Areas:** End hose pipes can reach areas that might be inaccessible to other equipment or vehicles, such as narrow pathways or areas with restricted entry.

It's important to note that while concrete end hose pipes offer numerous advantages, proper training, maintenance, and adherence to safety protocols are crucial to ensure their effective and safe use. Construction professionals should always follow manufacturer guidelines and industry best practices when operating concrete pumping equipment.

Type of Concrete End Hose Pipe

Concrete end hose pipes come in various types and configurations to suit different concrete pumping applications, site requirements, and equipment setups. Here are some common types of concrete end hose pipes:

- **Standard Concrete End Hose Pipe:** These are the most basic and commonly used types of end hose pipes. They are designed to handle the general requirements of concrete pumping in various construction projects.

- **High-Pressure Concrete End Hose Pipe:** These hoses are reinforced with additional layers of high-strength materials to withstand higher pumping pressures. They are suitable for projects that require pumping concrete over long distances or to elevated areas.

- **Reducing Concrete End Hose Pipe:** These hoses have varying diameters along their length, with one end having a larger diameter and the other end tapering down to a smaller diameter. This type of hose can help manage pressure fluctuations and optimize concrete flow in different sections of the pumping process.

- **Flexible Concrete End Hose Pipe:** These hoses are designed to be exceptionally flexible, allowing them to navigate tight corners, obstacles, and complex construction layouts. They are ideal for projects that demand precise and flexible concrete placement.

- **Extended Reach Concrete End Hose Pipe:** These hoses are longer than standard hoses, allowing concrete to be pumped to more distant or elevated locations. They are commonly used in high-rise construction projects.

- **Wire-Reinforced Concrete End Hose Pipe:** These hoses have a higher number of steel wire reinforcement layers for added strength and durability. They are suitable for heavy-duty applications where concrete pumping is done under demanding conditions.

- **Twin Wall Concrete End Hose Pipe:** Twin wall hoses consist of an inner and outer tube with an air gap between them. This design helps to reduce heat transfer, keeping the concrete cooler during pumping. Cooler concrete can have improved workability and set times.

- **Static-Resistant Concrete End Hose Pipe:** These hoses are designed to dissipate static electricity that can build up during concrete pumping. This feature is especially important when pumping in areas with flammable materials or explosive atmospheres.

- **Specialty Concrete End Hose Pipe:** Some hoses are designed for specific types of concrete or specialized applications. For example, shotcrete hoses are designed for pumping shotcrete (sprayed concrete), which has specific consistency requirements.

- **Abrasion-Resistant Concrete End Hose Pipe:** These hoses are reinforced with materials that offer enhanced resistance to the abrasive nature of concrete, ensuring a longer service life.

- **Corrosion-Resistant Concrete End Hose Pipe:** For applications where the pumped concrete may contain corrosive materials or chemicals, these hoses are made from materials that resist corrosion.

It's important to select the appropriate type of concrete end hose pipe based on the specific project requirements, pumping equipment, and the nature of the concrete being used. Consulting with manufacturers, suppliers, and experienced professionals can help ensure that the right type of hose is chosen for a particular construction project.

Maintenance and Care

Maintaining and caring for concrete end hose pipes is crucial to ensure their longevity, safety, and optimal performance. Proper maintenance practices can prevent accidents, extend the hose's lifespan, and maintain the quality of the concrete being pumped. Here are some detailed steps and tips for maintaining and caring for concrete end hose pipes:

- **Regular Visual Inspection:**

- Before and after each use, visually inspect the hose for signs of wear, cuts, bulges, kinks, and other damage.

- Check the end fittings, flanges, and connections for any signs of leaks, corrosion, or damage.

- Look for any loose or damaged bend restrictors, protective sleeves, or safety devices.

- **Cleaning:**

- Clean the exterior of the hose after every use to remove concrete residue and debris. Use water or a gentle cleaning solution to prevent buildup.

- Avoid using abrasive materials or chemicals that could damage the hose's surface.

- **Proper Handling:**

- Avoid dragging the hose over rough surfaces or sharp edges that could cause abrasion or cuts.

- Lift and carry the hose properly, supporting its weight evenly to prevent strain on the fittings and connections.

- **Storage:**

- Store the hose in a clean, dry, and well-ventilated area away from direct sunlight and harsh weather conditions.

- Hang the hose off the ground on hose racks or hooks to prevent damage and kinking.

- **Bending and Kinking:**

- Avoid excessive bending and kinking of the hose, as this can weaken the structure and obstruct the concrete flow.

- If a bend restrictor is provided, ensure it's in the proper position to prevent sharp bends.

- **Pressure Rating:**

- Always use the hose within its specified pressure rating. Operating the hose above its recommended pressure can lead to failure.

- **Avoid Twisting:**

- Prevent twisting of the hose during operation, as this can cause stress and damage.

- **Safety Devices:**

- Ensure that anti-whip devices and safety cables are in place and functioning correctly.

- These devices help control hose movement in case of detachment.

- **Professional Inspection:**

- Schedule regular professional inspections by trained personnel to assess the hose's overall condition and identify hidden issues.

- **Documentation:**

- Maintain a record of inspections, maintenance activities, and replacements for each hose. This record can help track the history of the hose and ensure compliance with safety standards.

- **Manufacturer's Guidelines:**

- Follow the manufacturer's maintenance recommendations and guidelines specific to your hose model.

- **Replacement:**

- **Operator Training:**

- **Consult Experts:**

- **Operator Training:**

- **Safety Equipment:**

- **Anti-Whip Devices:**

- **Safety Cables:**

- **Communication:**

- **Secure the Hose:**

- **Hose Handling:**

- **Proper Placement:**

- **Avoid Overloading:**

- **Clear Area:**

- **Inspect Regularly:**

- **Prevent Kinks and Twists:**

- **Emergency Shutdown:**

- **Work Zone Marking:**

- **Safety Guidelines:**

- **Emergency Response Plan:**

- **Qualified Personnel:**

- **Preparation and Inspection:**

- **Personal Protective Equipment (PPE):**

- **Positioning and Setup:**

- **Attaching the Hose:**

- **Clear Pathways:**

- **Guiding the Hose:**

- **Communication:**

- **Concrete Flow Control:**

- **Precision Pouring:**

- **Avoid Overloading:**

- **Safety During Pouring:**

- **Constant Supervision:**

- **Shutting Down:**

- **Cleaning and Maintenance:**

- **Regular Inspection:**

- **Emergency Response Plan:**

- **Training:**

- **Kinking or Bending:**

- **Abrasion and Wear:**

- **Concrete Blockages:**

- **Pressure Fluctuations:**

- **Leakage at Connections:**

- **Hose Detachment ("Whipping"):**

- **Excessive Weight and Pressure:**

- **Environmental Conditions:**

- **Equipment Compatibility:**

- **Improper Handling:**

- **Maintenance Neglect:**

- **Communication Issues:**

- **High-Rise Buildings:**

- **Bridge Construction:**

- **Tunnels and Underground Structures:**

- **Tight Urban Areas:**

- **Retaining Walls and Foundations:**

- **Dams and Reservoirs:**

- **Slope Stabilization:**

- **Decorative Concrete:**

- **Floor Slabs and Pavements:**

- **Remote Locations:**

- **Culverts and Drainage Systems:**

- **Repair and Restoration:**

- **Components:** Concrete end hose pipes consist of inner tubes, reinforcement layers, protective covers, end fittings, flanges, bend restrictors, and safety devices. These elements work together to ensure durability, flexibility, and safety during concrete pumping.

- **Working Principle:** Concrete is pumped from a mixing source to the end hose pipe, which guides the concrete to its intended location. Hydraulic pressure propels the concrete through the hose, facilitating precise placement.

- **Advantages:** Using concrete end hose pipes offers advantages like accurate concrete placement, flexibility, extended reach, reduced waste, enhanced safety, and cost efficiency in construction projects.

- **Maintenance and Care:** Regular maintenance involves inspections, cleanliness, avoiding kinks, proper storage, and adherence to manufacturer guidelines. Safety devices, professional inspections, and trained personnel are crucial for safe operation.

- **Safety Measures:** Safety measures include operator training, appropriate safety gear, anti-whip devices, safety cables, communication, and compliance with manufacturer guidelines to prevent accidents.

- **Proper Handling and Operation:** Correct handling entails preparation, communication, positioning, accurate guiding, pressure control, and adherence to safety protocols for safe and efficient concrete placement.

- **Challenges and Troubleshooting:** Challenges such as kinking, abrasion, blockages, pressure fluctuations, and hose detachment can be addressed through proper handling, maintenance, communication, and adherence to guidelines.

- **Applications:** Concrete end hose pipes find applications in various construction scenarios, including high-rise buildings, bridges, tunnels, tight urban spaces, dams, decorative work, and more, due to their flexibility and reach.

- **Inner Tube:** The innermost layer of the hose is typically made of rubber or other abrasion-resistant materials. This layer directly comes into contact with the flowing concrete and protects the hose from wear caused by the abrasive particles in the concrete mix.

- **Reinforcement Layers:** Surrounding the inner tube are layers of reinforcement, usually made of high-strength materials like steel wires or fabric. These layers provide the hose with its strength and flexibility, allowing it to handle the pressure generated by the pumping process without collapsing or kinking.

- **Outer Cover:** The outermost layer is a protective cover that shields the hose from environmental factors, physical damage, and exposure to sunlight and chemicals. This layer enhances the overall durability and longevity of the hose.

- **Length:** The length of the hose can vary depending on the distance between the concrete pump and the pouring site. Longer hoses are required for projects with greater distances between these two points.

- **Diameter:** The diameter of the hose can also vary. Larger diameters are used for projects that require higher concrete flow rates.

- **Fittings:** The hose is equipped with fittings at both ends to connect it to the concrete pump outlet and the delivery point. These fittings are usually made of hardened steel to withstand the pressure and ensure a secure connection.

- **Inner Tube:**

- **Reinforcement Layers:**

- **Wire or Fabric Mesh:**

- **Outer Cover:**

- **End Fittings:**

- **Flanges and Couplings:**

- **Anti-Kink Sleeves:**

- **Identification Markings:**

- **Concrete Pumping Equipment Setup:**

- **Concrete Mixing and Loading:**

- **Hydraulic Pressure Generation:**

- **Concrete Transfer through the Pipeline:**

- **Role of the Concrete End Hose:**

- **Concrete Placement:**

- **Continuous Process:**

- **Precise Concrete Placement:**

- **Access to Remote Areas:**

- **Reduced Labor Intensity:**

- **Faster Concrete Placement:**

- **Higher Concrete Output:**

- **Improved Concrete Quality:**

- **Reduced Formwork Impact:**

- **Enhanced Safety:**

- **Flexibility and Adaptability:**

- **Economical and Cost-Effective:**

- **Environmentally Friendly:**

- **Standard Flexible Hose:**

- **Steel Wire-Reinforced Hose:**

- **Fabric-Reinforced Hose:**

- **Reducing Hoses:**

- **Hardened End Hoses:**

- **Long-Reach Hoses:**

- **Wire-Braided Hose:**

- **Boom Hoses:**

- **Anti-Static Hoses:**

- **Composite Hoses:**

- **Regular Inspection:**

- **Prevent Abrasion:**

- **Clean After Use:**

- **Store Properly:**

- **Avoid Kinks:**

- **Inspect Fittings:**

- **Replace Worn Parts:**

- **Pressure Testing:**

- **Avoid Overbending:**

- **Use Compatible Concrete Mixes:**

- **Keep Records:**

- **Training and Operator Awareness:**

- **Operator Training:**

- **Personal Protective Equipment (PPE):**

- **Safe Distance:**

- **Barricades and Warning Signs:**

- **Secure Fittings:**

- **Pressure Relief Valve:**

- **Bending and Flexing:**

- **Hose Handling:**

- **Avoid Hose Whipping:**

- **Regular Inspections:**

- **Proper Pump Placement:**

- **Emergency Stop:**

- **Communication:**

- **Emergency Response Plan:**

- **Training and Familiarization:**

- **Personal Protective Equipment (PPE):**

- **Pre-Operation Inspection:**

- **Secure Setup:**

- **Attach the Hose:**

- **Prevent Kinks and Tangles:**

- **Positioning and Movement:**

- **Concrete Flow Control:**

- **Avoid Abrasion:**

- **Avoid Hose Whipping:**

- **Safe Removal:**

- **Cleaning:**

- **Storage and Maintenance:**

- **Emergency Procedures:**

- **Communication:**

- **Hose Blockages:**

- **Hose Wear and Abrasion:**

- **Kinking and Twisting:**

- **Leakage at Fittings:**

- **Concrete Segregation:**

- **Excessive Pressure:**

- **Hose Whipping:**

- **Excessive Distance or Height:**

- **Equipment Malfunctions:**

- **Weather Conditions:**

- **High-Rise Buildings:**

- **Bridges and Viaducts:**

- **Tunnels and Underground Structures:**

- **Industrial Facilities:**

- **Infrastructure Projects:**

- **Precast Concrete Elements:**

- **Residential Construction:**

- **Entertainment and Stadiums:**

- **Renovation and Restoration:**

- **Remote or Challenging Sites:**

- If you notice significant damage, wear, or any issues affecting the hose's integrity, replace it with a new one. Avoid attempting to repair a damaged hose, as it may compromise its safety.

- Ensure that operators are properly trained in the correct use, handling, and maintenance of concrete end hose pipes.

- If you're uncertain about any maintenance procedures or encounter significant damage, consult with the hose manufacturer or a qualified professional.

By following these comprehensive maintenance practices, you can ensure the safety and effectiveness of your concrete end hose pipe, contributing to successful construction projects and a safer working environment.

Safety Measures

Safety is paramount when working with concrete end hose pipes and associated concrete pumping equipment. Concrete pumping involves high pressures, heavy machinery, and potential hazards, so it's crucial to implement strict safety measures to protect workers and ensure smooth operations. Here are important safety measures to consider when working with concrete end hose pipes:

- Provide comprehensive training to operators who will be handling the concrete pump and end hose pipe.

- Ensure they understand the equipment's operation, safety protocols, emergency procedures, and proper handling techniques.

- Operators and workers should wear appropriate personal protective equipment (PPE) such as hard hats, safety glasses, gloves, steel-toed boots, and high-visibility clothing.

- Install and maintain anti-whip devices at the end of the hose to prevent sudden and uncontrolled movements if the hose becomes detached.

- Attach safety cables to the hose and secure them to the pump and the delivery point. These cables prevent the hose from flailing in case of detachment.

- Establish clear communication between the pump operator, hose operator, and workers at the pouring site. Use hand signals, radios, or other appropriate methods.

- Ensure that the end hose pipe is securely attached to both the concrete pump's outlet and the delivery nozzle.

- Check for proper fittings, flange connections, and clamps.

- Avoid excessive pulling, tugging, or sudden movements of the hose. These actions can cause strain on the hose or lead to detachment.

- Position the hose in a way that avoids tripping hazards and does not obstruct walkways or access routes.

- Do not exceed the hose's maximum pressure rating. Overloading can lead to hose failure and accidents.

- Ensure that workers and bystanders are clear of the hose's path during pumping operations to prevent injury.

- Conduct thorough visual inspections of the hose, fittings, and connections before each use.

- Look for signs of wear, damage, corrosion, or leaks.

- Avoid kinking or twisting the hose during operation, as this can weaken the hose and hinder concrete flow.

- Ensure operators know how to quickly shut down the pump in case of an emergency or unexpected situation.

- Clearly mark the work zone where concrete is being poured to prevent unauthorized access.

- Develop and implement safety guidelines and procedures specific to concrete pumping operations.

- Regularly review and update these guidelines to incorporate best practices and lessons learned.

- Have a well-defined emergency response plan in place in case of accidents, hose detachment, or other unexpected incidents.

- Only allow trained and authorized personnel to operate the concrete pump and end hose pipe.

Remember that safety is a shared responsibility, and everyone involved in the operation, from operators to site supervisors, must prioritize safety at all times. Adhering to these safety measures can help prevent accidents, injuries, and damage to equipment while ensuring the successful completion of construction projects.

Proper Handling and Operation

Proper handling and operation of a concrete end hose pipe are crucial to ensure safety, efficiency, and the successful delivery of concrete to the intended location. Here's a step-by-step guide on how to handle and operate a concrete end hose pipe safely:

- Before use, visually inspect the hose for signs of wear, cuts, kinks, or damage.

- Ensure that the end fittings, flanges, and connections are secure and in good condition.

- Confirm that safety devices such as anti-whip systems and safety cables are properly installed and functional.

- Wear appropriate PPE, including safety glasses, hard hat, gloves, steel-toed boots, and high-visibility clothing.

- Position the concrete pump in a safe and stable location, considering the distance to the pouring site and potential obstacles.

- Attach the end hose pipe securely to the concrete pump's outlet and the delivery nozzle using the appropriate fittings and flanges.

- Double-check that all connections are tightened properly to prevent leaks.

- Ensure that the hose's pathway is clear of obstacles, debris, and tripping hazards.

- Maneuver the hose carefully to avoid excessive bending, kinking, or twisting.

- Use smooth and controlled movements to guide the hose's path.

- Establish clear communication with the pump operator and other workers at the pouring site using hand signals, radios, or other agreed-upon methods.

- Control the concrete flow rate using the pump's controls, adjusting it to match the required pouring rate and consistency.

- Guide the end hose pipe to the desired pouring location with controlled movements.

- Avoid sudden or jerky movements that could lead to hose detachment or uncontrolled concrete flow.

- Monitor the pressure gauge to ensure that the hose is not subjected to pressures higher than its maximum rating.

- Ensure that workers and bystanders stay clear of the hose's path and the pouring area to prevent accidents.

- Continuously monitor the hose's condition, the concrete flow, and the surrounding environment throughout the pouring process.

- When the pouring is complete, gradually reduce the concrete flow rate before stopping the pump.

- Carefully detach the end hose pipe from the delivery nozzle once the concrete flow has stopped.

- After use, clean the exterior of the hose to remove concrete residue and debris.

- Store the hose properly in a clean and dry area, away from direct sunlight and harsh weather conditions.

- Perform regular visual inspections of the hose, fittings, and connections to identify any signs of wear or damage.

- Be familiar with the site's emergency response plan in case of accidents, hose detachment, or unexpected incidents.

- Ensure that operators are properly trained in the safe handling and operation of concrete end hose pipes.

By following these proper handling and operation steps, you can ensure the safety of workers, prevent damage to equipment, and achieve accurate and efficient concrete placement in construction projects. Always prioritize safety and adhere to manufacturer guidelines and industry best practices.

Common Challenges and Troubleshooting

Working with concrete end hose pipes can present certain challenges that may affect the efficiency and safety of concrete pumping operations. Here are some common challenges that can arise with concrete end hose pipes and potential troubleshooting steps to address them:

- Challenge: The hose may kink or bend excessively, obstructing the concrete flow.

- Troubleshooting: Ensure that the hose is properly supported and not subjected to sharp bends. Use bend restrictors to prevent excessive bending.

- Challenge: Concrete's abrasive nature can cause wear on the hose's surface.

- Troubleshooting: Inspect the hose regularly for signs of abrasion or damage. Consider using abrasion-resistant hoses or protective sleeves.

- Challenge: Concrete can occasionally clog or block the hose, disrupting the pumping process.

- Troubleshooting: Adjust the concrete mixture's consistency to prevent blockages. If a blockage occurs, stop pumping, reverse the pump briefly, or use a rubber mallet to gently tap the hose.

- Challenge: Pressure fluctuations can affect the smooth flow of concrete through the hose.

- Troubleshooting: Monitor the pressure gauge and adjust the pump's controls to maintain a consistent pressure. Ensure that the hose is not kinked or obstructed.

- Challenge: Leakage may occur at the connections between the hose and fittings.

- Troubleshooting: Check for proper tightening of fittings and flanges. Replace worn gaskets or seals if necessary.

- Challenge: In extreme cases, the hose can detach from the pump or nozzle, causing uncontrolled movement ("whipping").

- Troubleshooting: Install anti-whip devices and safety cables as recommended by the manufacturer. Follow proper attachment procedures and avoid sudden movements.

- Challenge: If the concrete mixture is too heavy or the pumping pressure is too high, the hose may be strained.

- Troubleshooting: Ensure that the concrete mix is within acceptable specifications and that the pump's pressure is within the hose's rated capacity.

- Challenge: Extreme temperatures, freezing conditions, or exposure to harsh weather can affect the hose's integrity.

- Troubleshooting: Store hoses properly when not in use and consider using hoses designed for specific temperature ranges.

- Challenge: Incompatibility between the hose and the concrete pump or delivery nozzle may arise.

- Troubleshooting: Ensure that the hose's fittings and flanges match the pump's and nozzle's specifications. Use adapters if necessary.

- Challenge: Incorrect handling, bending, or dragging of the hose can lead to damage.

- Troubleshooting: Train operators in proper handling techniques. Avoid dragging the hose over rough surfaces or sharp edges.

- Challenge: Lack of regular maintenance can lead to undetected wear and potential failures.

- Troubleshooting: Implement a comprehensive maintenance schedule, conduct inspections, and address any issues promptly.

- Challenge: Lack of effective communication between pump operators, hose operators, and workers can lead to confusion and accidents.

- Troubleshooting: Establish clear communication protocols and signals. Use radios, hand signals, or designated communication methods.

Addressing these common challenges and promptly troubleshooting issues will help ensure the safe and efficient operation of concrete end hose pipes and overall concrete pumping operations. Always prioritize safety, follow manufacturer guidelines, and involve experienced personnel in handling and troubleshooting tasks.

Real- Life Applications and Examples

Concrete end hose pipes are widely used in various real-life construction applications to facilitate the efficient and accurate placement of concrete in challenging or remote locations. Here are some examples of their applications:

- In the construction of tall buildings, concrete end hose pipes are essential for delivering concrete to upper floors and elevated surfaces. The flexibility and reach of the hose enable efficient concrete pouring at various heights.

- When building bridges, end hose pipes are used to transport concrete to hard-to-reach areas, such as the undersides of bridge decks or between structural elements.

- In tunnel construction, where access may be limited, end hose pipes allow concrete to be pumped to the tunnel interior, ensuring proper concrete placement in confined spaces.

- In densely populated urban areas with limited space for large construction equipment, end hose pipes can pump concrete over obstacles and between buildings.

- When constructing retaining walls or foundations, end hose pipes can accurately place concrete in excavated areas or behind formwork, ensuring proper compaction.

- In dam and reservoir construction, where concrete needs to be placed in remote and challenging locations, end hose pipes enable controlled pouring even in uneven terrain.

- When stabilizing slopes or embankments, end hose pipes can deliver concrete to steep or inaccessible areas, helping to prevent erosion and improve structural stability.

- In architectural projects that involve decorative concrete work, end hose pipes can accurately place concrete to achieve intricate designs and patterns.

- For large floor slabs or pavement projects, end hose pipes can efficiently distribute concrete over wide areas, ensuring even thickness and a consistent finish.

- In remote construction sites, such as in rural areas or on offshore platforms, end hose pipes are used to transport concrete where traditional methods may be impractical.

- In the construction of culverts and drainage systems, end hose pipes can place concrete inside confined spaces, ensuring proper installation.

- During repair or restoration projects, end hose pipes can deliver concrete to repair damaged structures without the need for extensive dismantling.

These examples highlight the versatility and importance of concrete end hose pipes in modern construction projects. By enabling precise concrete placement in challenging environments, these hoses contribute to the efficiency, safety, and successful completion of a wide range of construction tasks.

Conclusion and Recap

In conclusion, the concrete end hose pipe is a vital component in the construction industry, enabling efficient and precise concrete placement in diverse and challenging scenarios. This flexible conduit bridges the gap between concrete pumps and delivery points, allowing for controlled concrete flow over long distances, elevated surfaces, and confined spaces. Here's a recap of key points discussed:

Concrete end hose pipes are indispensable tools that enhance the efficiency, safety, and success of concrete pumping operations in construction. By following best practices, maintaining safety protocols, and conducting regular maintenance, construction professionals can harness the full potential of these hoses to achieve accurate and efficient concrete placement in a wide array of construction projects.

Introduction to concreate End Hose pipe

A concrete end hose pipe, also known simply as an end hose or concrete pump hose, is an essential component in the construction industry, specifically in concrete pumping operations. It plays a critical role in transferring concrete from the concrete pump to the desired location, typically a construction site where the concrete is being poured for various structures such as buildings, bridges, roads, and more.

Here's an introduction to the concrete end hose pipe:

**Function:**

The primary function of a concrete end hose pipe is to provide a flexible and durable conduit for the flow of concrete from the concrete pump to the placement area. The hose is designed to withstand the high pressure generated by the concrete pump and the abrasive nature of the concrete mixture.

**Components:**

A typical concrete end hose pipe consists of several layers of materials designed to handle the demands of concrete pumping:

**Features:**

Concrete end hose pipes are designed with specific features to ensure efficient and safe concrete pumping:

**Maintenance:**

Regular maintenance and inspection of the concrete end hose pipe are crucial to ensure its safety and performance. Abrasion, kinks, cuts, and other forms of damage can compromise the integrity of the hose and lead to leaks or other issues.

In conclusion, a concrete end hose pipe is an integral part of concrete pumping equipment, allowing for the efficient and precise delivery of concrete to construction sites. Its durability, flexibility, and resistance to abrasion make it an essential tool in modern construction practices. Proper usage, maintenance, and inspection are essential to ensure the safety and success of concrete pumping operations.

Components of a Concreate End Hose Pipe

A concrete end hose pipe is composed of several key components designed to withstand the high pressures, abrasive materials, and challenging conditions encountered during concrete pumping operations. These components work together to ensure the hose's durability, flexibility, and safe performance. The main components of a concrete end hose pipe include:

The inner tube is the innermost layer of the hose, directly in contact with the concrete being pumped. It's made from a high-quality rubber compound or other abrasion-resistant material to withstand the abrasive nature of concrete. The inner tube prevents the concrete mixture from directly contacting the reinforcement layers, protecting them from wear and corrosion.

The reinforcement layers are responsible for providing the hose with strength, flexibility, and the ability to withstand the high pressures generated by the concrete pumping process. These layers are typically made of high-tensile steel wires or fabric cords. The layers are usually braided or wound in a spiral pattern to distribute stress evenly and prevent kinking or collapsing under pressure.

Some hoses have an additional layer of wire or fabric mesh between the inner tube and the outer cover. This layer further enhances the hose's strength and flexibility, helping it maintain its shape even under extreme conditions.

The outer cover is the protective layer that surrounds the reinforcement layers. It shields the hose from external factors such as physical damage, sunlight, weather, and chemicals. The outer cover is usually made from synthetic rubber, PVC, or polyurethane to provide resistance against abrasion and environmental conditions.

The end fittings are crucial components that connect the concrete end hose pipe to the concrete pump's outlet and the nozzle or delivery point. These fittings are typically made of hardened steel to withstand the high pressures and secure the hose connections. They are designed to ensure a tight seal and prevent any leakage during the pumping process.

Flanges are the circular discs located at the ends of the hose that attach to the end fittings. They have holes to align with bolts, allowing for secure attachment to the pump and delivery point. Couplings are similar but serve to connect two hoses together for extended reach when needed.

Some hoses may have anti-kink sleeves or coils placed along their length. These components help prevent the hose from bending excessively, which could lead to kinks or blockages that impede the concrete flow.

Many hoses come with identification markings, including information about their specifications, working pressure, manufacturer, and other important details. These markings help ensure proper usage and maintenance.

Each of these components plays a critical role in the overall performance, durability, and safety of a concrete end hose pipe during concrete pumping operations. Regular inspection, maintenance, and proper usage are essential to ensure the hose's reliability and to prevent any potential issues that could disrupt the concrete placement process.

Working Principle

The working principle of a concrete end hose, also known as a concrete pump hose, is closely tied to the process of concrete pumping. Concrete pumping is a method used in construction to efficiently transport concrete from the concrete pump to the desired location, often a construction site where the concrete is being poured. The end hose is a crucial component in this process, enabling the smooth and controlled transfer of concrete.

Here's how the working principle of a concrete end hose operates:

Concrete pumping typically involves a concrete pump, which is a machine that uses a hydraulic system to create pressure and flow to move concrete through a pipeline. The concrete pump is usually mounted on a truck or a trailer and consists of a hopper, a hydraulic pump, and a system for delivering the concrete.

Concrete is initially mixed in a mixing truck or at a batching plant. Once the concrete mixture is ready, it's loaded into the hopper of the concrete pump. The hopper acts as a temporary storage container for the concrete.

The hydraulic pump in the concrete pump generates pressure by using hydraulic oil to move pistons or cylinders. This pressure forces the concrete through the pipeline.

The concrete is pushed by the hydraulic pressure through the pipeline, which consists of rigid pipes and flexible hoses. The pipeline's purpose is to transport the concrete from the pump to the point of placement.

The concrete end hose is attached to the last section of the pipeline. It's a flexible hose designed to handle the abrasive nature of concrete and the pressure generated by the pump. The hose allows the concrete to be directed accurately to the desired location for pouring. It provides flexibility and mobility, allowing the concrete pump operator to maneuver the hose to access hard-to-reach areas, high or distant locations, or specific parts of a construction site.

The concrete end hose is operated by a skilled pump operator who guides the hose's movement to control the flow of concrete. By manipulating the hose, the operator can adjust the angle and direction of the concrete flow, ensuring precise placement in accordance with the construction plans.

As the concrete pump operates, the hydraulic pump maintains a consistent pressure to push the concrete through the pipeline and into the end hose. The process is continuous, allowing for a steady and controlled delivery of concrete to the construction site.

In summary, the working principle of a concrete end hose involves connecting it to the last section of the concrete pipeline and using hydraulic pressure to transfer concrete from the pump's hopper to the hose. The hose's flexibility and maneuverability enable accurate placement of the concrete at the construction site, helping achieve efficient and precise concrete pouring for various construction projects. Proper coordination between the pump operator, pump equipment, and the end hose is essential for successful concrete pumping operations.

Advantages of Using a concreate End Hose Pipe

Using a concrete end hose pipe in concrete pumping operations offers several advantages that contribute to the efficiency, safety, and quality of the construction process. Here are some of the key advantages of using a concrete end hose pipe:

Concrete end hose pipes provide the flexibility and maneuverability required to accurately place concrete at specific locations within a construction site. This precision is especially crucial when pouring concrete in hard-to-reach or elevated areas, ensuring that the concrete is delivered exactly where it's needed.

The flexibility of the end hose allows operators to reach areas that might be inaccessible by traditional pouring methods. This is particularly valuable for projects with complex architectural designs or where obstacles hinder direct access.

Using a concrete end hose pipe reduces the need for manual labor to move and distribute concrete across the construction site. This can lead to increased productivity and reduced physical strain on workers.

Concrete pumping with an end hose is generally faster than manual methods. The controlled flow of concrete through the hose enables rapid and consistent placement, speeding up the construction process.

Concrete pumps, in combination with end hose pipes, can deliver a larger volume of concrete in a shorter time compared to traditional methods. This is particularly beneficial for larger-scale projects that require a significant amount of concrete.

The smooth and controlled flow of concrete through the hose helps minimize segregation and air pockets within the mixture. This results in a more homogenous and higher-quality concrete that contributes to the structural integrity of the finished project.

Concrete end hose pipes allow precise placement of concrete, reducing the need for excessive formwork adjustments or rework. This results in a smoother concrete surface finish and fewer imperfections.

Concrete pumping operations using end hose pipes can improve job site safety by minimizing the risks associated with manual concrete handling, such as heavy lifting and potential exposure to hazardous materials.

End hose pipes are available in various lengths and diameters, allowing operators to choose the most suitable option for the project's requirements. This adaptability ensures efficient concrete placement in a wide range of construction scenarios.

While initial setup costs for concrete pumping equipment might be higher than traditional methods, the time saved, reduced labor requirements, and increased productivity can lead to cost savings over the course of a project.

Concrete pumping with end hose pipes can lead to a reduction in material wastage and a more efficient use of resources, contributing to more sustainable construction practices.

In summary, the use of a concrete end hose pipe offers numerous benefits that contribute to faster construction, improved concrete quality, enhanced safety, and overall cost-effectiveness. It is a valuable tool for modern construction projects, particularly those that require precise concrete placement and efficient distribution of materials.

Type of Concreate End Hose Pipe

Concrete end hose pipes come in various types and designs, each suited for specific applications and requirements. The choice of a particular type depends on factors such as the project's scale, the distance between the concrete pump and the placement site, the concrete mix characteristics, and any special considerations. Here are some common types of concrete end hose pipes:

This is the most common type of concrete end hose pipe. It consists of multiple layers, including an inner tube, reinforcement layers (usually made of steel wires or fabric), and an outer cover. Standard flexible hoses are versatile and used for a wide range of concrete pumping tasks, providing durability, flexibility, and abrasion resistance.

Steel wire-reinforced hoses are designed with additional layers of high-tensile steel wires in the reinforcement, enhancing the hose's strength and resistance to high pressures. These hoses are suitable for projects that demand higher concrete flow rates and pressures.

Fabric-reinforced hoses use layers of fabric cords, such as nylon or polyester, in their reinforcement. These hoses are lighter in weight compared to steel wire-reinforced hoses, making them easier to handle and maneuver. They are often used for shorter-distance concrete placements.

These hoses have a diameter that tapers down along the length of the hose. They are used to transition between different pipe sizes or to connect sections of different diameters within the concrete pumping system.

Hardened end hoses are reinforced with additional layers of abrasion-resistant materials, such as hardened rubber or polyurethane, to provide extra durability when pumping highly abrasive concrete mixes.

Long-reach hoses are designed to cover longer distances between the concrete pump and the placement site. These hoses are often used in projects with challenging access or where the pump needs to be positioned farther away from the work area.

Wire-braided hoses are reinforced with a braided layer of steel wires, enhancing their strength while maintaining flexibility. They are commonly used in applications that require higher working pressures.

Boom hoses are specialized hoses used in concrete pump truck booms. These booms extend to place concrete precisely in elevated or distant areas. Boom hoses are designed to handle the extreme movements and stresses associated with boom operation.

Anti-static hoses are equipped with a conductive layer to prevent the build-up of static electricity. They are used in applications where the conveyed material is prone to static discharge, which could be hazardous.

Composite hoses combine different materials in their construction to optimize performance. These hoses might incorporate features like an inner lining resistant to the conveyed material and a flexible outer cover for added protection.

When selecting a concrete end hose pipe, it's important to consider factors such as the working pressure, concrete mixture properties, hose length, diameter, and the specific demands of the construction project. Consulting with professionals experienced in concrete pumping can help ensure the right type of hose is chosen for optimal performance and safety.

Maintenance and Care

Proper maintenance and care of a concrete end hose pipe are essential to ensure its longevity, safety, and optimal performance during concrete pumping operations. Regular inspection and maintenance can help prevent potential issues and downtime. Here are some important maintenance and care tips for concrete end hose pipes:

Conduct thorough visual inspections of the entire hose, including the inner tube, reinforcement layers, fittings, and outer cover. Look for signs of wear, abrasion, cuts, punctures, bulges, and any damage that could compromise the hose's integrity.

Concrete contains abrasive particles that can wear down the inner lining of the hose over time. To prevent excessive abrasion, avoid dragging the hose on rough surfaces, and make sure it doesn't come into contact with sharp edges or debris.

After each use, rinse the hose's interior with water to remove any residual concrete or debris. This prevents the concrete from hardening inside the hose, which could lead to blockages or reduced flow during the next use.

Store the hose in a cool, dry place away from direct sunlight and extreme temperatures. Hanging the hose on a hose rack or a special hose holder helps prevent kinks, twists, and unnecessary stress on the hose.

Kinks in the hose can restrict the flow of concrete and lead to damage. Handle the hose carefully during operation to prevent kinks, and use anti-kink sleeves or coils if necessary.

Regularly check the end fittings, flanges, and couplings for signs of wear, corrosion, or damage. Ensure that they are securely attached and provide a proper seal to prevent leaks.

If you notice any significant wear, cuts, or damage to the hose or its components, replace them promptly to prevent further deterioration and potential safety hazards.

Periodically pressure test the hose to ensure it can withstand the expected operating pressures without any leakage or failure. Consult the manufacturer's recommendations for the appropriate testing procedures and intervals.

Overbending the hose beyond its recommended bend radius can weaken the reinforcement layers and lead to hose failure. Follow the manufacturer's guidelines for bending and handling the hose.

Certain aggressive or highly abrasive concrete mixes can accelerate hose wear. If possible, adjust the concrete mixture to reduce abrasion on the hose.

Maintain records of the hose's usage, inspections, maintenance, and any repairs or replacements. This documentation can help track the hose's history and inform future maintenance decisions.

Ensure that concrete pump operators are trained in proper hose handling, usage, and maintenance practices. Operator awareness and diligence can significantly contribute to extending the hose's lifespan.

By following these maintenance and care practices, you can ensure that your concrete end hose pipe remains in good condition, performs reliably, and contributes to the safe and efficient completion of your construction projects. Always refer to the manufacturer's guidelines and recommendations for specific maintenance procedures and schedules.

Safety Measures

Ensuring safety during concrete pumping operations is paramount, and this includes implementing specific safety measures for concrete end hose pipes. Handling high-pressure equipment and abrasive materials requires careful attention to safety protocols to prevent accidents, injuries, and damage. Here are some important safety measures to consider when using concrete end hose pipes:

Ensure that all personnel involved in concrete pumping operations, including pump operators and ground crew, are properly trained and knowledgeable about the equipment, procedures, and potential hazards.

Require everyone on the job site to wear appropriate PPE, including safety helmets, eye protection, ear protection, gloves, and steel-toed boots. Additional PPE might be necessary based on the specific hazards present.

Maintain a safe distance from the end of the hose while concrete is being pumped. Stay clear of the hose's discharge point to avoid being in the path of the concrete flow.

Establish clear barricades and warning signs around the pumping area to prevent unauthorized access and to keep personnel and equipment at a safe distance from the hose's movement.

Ensure that all hose fittings, flanges, and couplings are properly secured before starting the pumping operation to prevent leaks, disconnections, or blowouts.

Install a pressure relief valve in the concrete pumping system to prevent excessive pressure buildup, which could lead to hose failure or other equipment malfunctions.

Follow the manufacturer's guidelines for the bending radius and flexibility limits of the hose. Avoid overbending, kinking, or twisting the hose, as this could weaken the hose structure and result in failure.

Handle the hose with care and avoid dragging it on rough surfaces that could cause abrasion. Use anti-kink sleeves or coils to prevent kinks and ensure smooth concrete flow.

Prevent hose whipping by avoiding abrupt movements, releasing pressure gradually, and securing the hose's end when disconnecting.

Conduct frequent visual inspections of the hose for signs of wear, damage, or leaks. Inspect the fittings, reinforcement layers, and outer cover to ensure they are in good condition.

Position the concrete pump in a stable and secure location to prevent tipping or collapsing. Follow proper setup guidelines and ensure the pump's stability during operation.

Make sure the concrete pump operator knows how to use the emergency stop button on the pump to quickly halt the pumping operation in case of a sudden issue or hazard.

Establish clear communication between the pump operator and ground crew. Use hand signals, radios, or other communication devices to coordinate concrete placement and ensure everyone's safety.

Develop and communicate an emergency response plan that outlines procedures for handling accidents, spills, equipment failures, or injuries during concrete pumping operations.

Remember that safety is a collaborative effort that involves all personnel on the job site. Regular training, open communication, and a commitment to following established safety protocols are crucial to preventing accidents and maintaining a safe working environment during concrete pumping with end hose pipes.

Proper Handling and Operation

Proper handling and operation of a concrete end hose pipe are crucial to ensure the safety of personnel, the integrity of the equipment, and the success of concrete pumping operations. Here's a step-by-step guide on how to handle and operate a concrete end hose pipe safely and effectively:

Ensure that all personnel involved in concrete pumping operations are properly trained and familiar with the equipment, including the concrete pump, end hose pipe, fittings, and controls.

Before starting work, ensure that all workers are wearing the appropriate PPE, including safety helmets, eye protection, ear protection, gloves, and steel-toed boots.

Conduct a thorough visual inspection of the entire hose, checking for wear, abrasion, cuts, punctures, and other damage. Inspect the fittings, flanges, and couplings for proper attachment and any signs of wear.

Properly secure the concrete pump in a stable and level position to prevent tipping or collapsing during operation. Ensure that the pump is on a firm foundation and follows the manufacturer's setup guidelines.

Carefully attach the concrete end hose pipe to the pump's outlet and secure the fittings. Follow proper tightening procedures to prevent leaks.

Ensure the hose is unrolled smoothly and free of kinks or tangles. Avoid sharp bends and overbending the hose beyond its recommended bend radius.

Position the end hose pipe in a way that allows for safe and accurate concrete placement. Avoid placing the hose directly over workers or equipment. Use anti-kink sleeves or coils to prevent kinks and ensure smooth concrete flow.

Coordinate with the pump operator to control the flow of concrete through the hose. Use clear and consistent hand signals or communication devices to indicate when to start and stop the flow.

Keep the hose clear of abrasive surfaces, sharp objects, and debris that could cause wear or damage to the hose's outer cover.

When shutting down the pumping operation, release pressure gradually to avoid sudden hose whipping. Always secure the hose's end to prevent uncontrolled movement.

When disconnecting the hose, ensure the concrete flow has stopped, and the pressure has been relieved. Slowly detach the fittings and lower the hose gently to the ground, avoiding damage to the hose or nearby structures.

After concrete pumping, rinse the hose's interior with water to prevent concrete from hardening inside. Keep the hose clean to ensure smooth flow during future operations.

Properly store the hose in a dry and cool area away from direct sunlight. Regularly inspect and maintain the hose according to the manufacturer's guidelines.

Familiarize all personnel with emergency stop procedures and protocols for handling hose malfunctions, equipment failures, or other unforeseen incidents.

Maintain open and clear communication between the pump operator and the ground crew. Use hand signals or radios to coordinate concrete placement and ensure everyone's safety.

Remember that safety is a top priority throughout the concrete pumping process. By adhering to proper handling and operation practices, you can help ensure a safe and successful concrete pumping operation while extending the life of your concrete end hose pipe. Always follow manufacturer recommendations and industry best practices for the specific equipment and conditions you are working with.

Common Challenges and Troubleshooting

Concrete pumping operations using end hose pipes can encounter various challenges that may impact the efficiency, safety, and success of the process. Here are some common challenges that may arise during concrete pumping and troubleshooting steps to address them:

Issue: Blockages in the hose can occur due to hardened concrete, debris, or material segregation.

Troubleshooting:

- Release pressure and use a rubber mallet to gently tap the hose to dislodge any blockages.

- Gradually increase the concrete flow to push out the obstruction.

- Implement regular cleaning procedures to prevent blockages.

Issue: The abrasive nature of concrete can cause wear and tear on the inner tube and outer cover of the hose.

Troubleshooting:

- Use hardened or anti-abrasive hoses for more abrasive concrete mixes.

- Avoid dragging the hose on rough surfaces and sharp edges.

- Inspect the hose regularly for signs of wear and replace damaged sections promptly.

Issue: Improper handling or positioning can lead to kinks or twists in the hose, impeding the flow of concrete.

Troubleshooting:

- Avoid overbending or twisting the hose beyond its recommended bend radius.

- Use anti-kink sleeves or coils to prevent kinks.

- Train operators in proper hose handling techniques.

Issue: Improperly secured fittings, worn-out gaskets, or damaged flanges can lead to leaks.

Troubleshooting:

- Check fittings, flanges, and couplings for proper attachment and signs of wear.

- Replace damaged gaskets and tighten fittings as needed.

- Verify that all connections are properly sealed before pumping.

Issue: Segregation of concrete mix components can result in a non-homogeneous mixture and decreased pumping efficiency.

Troubleshooting:

- Adjust the concrete mix design to minimize segregation.

- Implement proper mix design and mixing techniques to ensure uniformity.

Issue: Pumping at excessively high pressures can strain the hose and other components of the pumping system.

Troubleshooting:

- Use pressure relief valves to prevent pressure buildup.

- Monitor and control the pumping pressure to stay within safe limits.

Issue: Sudden releases of pressure or improper handling can cause the hose to whip or move uncontrollably.

Troubleshooting:

- Gradually release pressure before disconnecting the hose.

- Secure the hose's end to prevent uncontrolled movement.

- Maintain proper communication between the pump operator and ground crew.

Issue: Long distances or heights can result in reduced concrete flow efficiency and increased pressure.

Troubleshooting:

- Use longer hoses or additional pumping equipment if needed.

- Consult with experienced operators to ensure the equipment is suitable for the distance or height required.

Issue: Malfunctions in the concrete pump, such as hydraulic issues or engine problems, can affect the entire pumping process.

Troubleshooting:

- Regularly inspect and maintain the concrete pump according to manufacturer guidelines.

- Address any equipment issues promptly to prevent interruptions in pumping.

Issue: Extreme weather conditions like cold temperatures or rain can affect the concrete mix and the performance of the hose.

Troubleshooting:

- Adjust the concrete mix design to accommodate temperature changes.

- Provide proper insulation or heating to prevent freezing or excessive cooling of the concrete mix.

In all cases, having a skilled and experienced concrete pump operator, as well as a well-maintained pumping system, can significantly reduce the likelihood of encountering these challenges and enable efficient troubleshooting when issues arise. Regular training, proper equipment maintenance, and adherence to safety protocols are key to successful concrete pumping operations.

Real-Life Applications and Examples

Concrete end hose pipes play a vital role in various construction projects where efficient and precise concrete placement is essential. Here are some real-life applications and examples of how concrete end hose pipes are used in different construction scenarios:

Concrete end hose pipes are frequently used in the construction of tall buildings. They allow concrete to be pumped to the upper floors, where traditional methods might be impractical or time-consuming. The flexibility of the hose enables accurate placement for columns, walls, and slabs at different levels.

When constructing bridges or viaducts, concrete end hose pipes are used to place concrete in areas that are hard to access or at elevated heights. This allows for efficient and precise concrete placement for bridge piers, abutments, and other structural elements.

In tunneling and underground construction, concrete end hose pipes are used to pump concrete into confined spaces or areas with limited access. This method ensures that concrete can be placed accurately for tunnel linings, underground chambers, and other subterranean structures.

Industries often require heavy-duty flooring or specialized concrete installations. Concrete end hose pipes are used to pour concrete in large, open areas, warehouses, manufacturing plants, and other industrial settings where fast and controlled concrete placement is necessary.

Concrete end hose pipes are essential in infrastructure projects such as roads, highways, and airports. They enable the placement of concrete for curbs, gutters, barriers, and pavement, even in tight or remote locations.

For precast concrete elements like beams, columns, and panels, concrete end hose pipes are used to fill molds with concrete mix accurately. This ensures that the precast elements have consistent quality and structural integrity.

Concrete end hose pipes are used in residential construction for pouring foundations, footings, retaining walls, and other structural components. They allow concrete to be placed precisely in tight spaces or around existing structures.

In the construction of entertainment venues, stadiums, and event spaces, concrete end hose pipes can be used to pour concrete for large seating areas, ramps, staircases, and other features.

During renovation or restoration projects, concrete end hose pipes are valuable for placing concrete in areas that require repair or reinforcement. They can help restore historical structures while preserving their original character.

Concrete end hose pipes are used in remote or difficult-to-reach locations, such as remote construction sites, islands, or mountainous terrain. They ensure concrete placement in areas where traditional methods may be impractical.

Concrete end hose pipes are versatile tools used in a wide range of construction projects to enhance efficiency, accuracy, and safety. Their flexibility, durability, and ability to handle high-pressure concrete flow make them indispensable in modern construction practices.

Conclusion and Recap

In conclusion, a concrete end hose pipe is a critical component in the realm of modern construction, enabling the efficient, precise, and safe placement of concrete in various projects. Throughout this discussion, we've covered its components, working principle, advantages, maintenance, safety measures, proper handling, troubleshooting, and real-life applications. Let's recap the key points:

- **Components:** A concrete end hose pipe consists of layers, including an inner tube, reinforcement layers, and an outer cover. These layers work together to handle the abrasive nature of concrete and the high pressures generated by the pumping process.

- **Working Principle:** Concrete end hose pipes are used in concrete pumping operations to transfer concrete from the pump to the desired location. The pump generates hydraulic pressure, pushing the concrete through the pipeline and into the flexible hose, which allows for precise placement.

- **Advantages:** Concrete end hose pipes offer benefits such as precise concrete placement, access to remote areas, reduced labor intensity, faster placement, improved concrete quality, and enhanced safety, among others.

- **Maintenance and Care:** Proper maintenance involves regular inspections, preventing abrasion, cleaning after use, correct storage, and prompt replacement of worn parts. These practices ensure the longevity and reliability of the hose.

- **Safety Measures:** Safety measures include operator training, proper PPE, safe distances, securing fittings, preventing kinks, emergency procedures, and effective communication to minimize risks during concrete pumping operations.

- **Proper Handling and Operation:** Proper handling involves pre-operation inspections, secure setup, avoiding kinks and tangles, positioning and movement, controlled concrete flow, safe removal, and adhering to manufacturer guidelines.

- **Common Challenges and Troubleshooting:** Common challenges include hose blockages, wear, kinking, leakage, segregation, excessive pressure, hose whipping, and more. Troubleshooting involves techniques to address these challenges and prevent disruptions.

- **Real-Life Applications:** Concrete end hose pipes find applications in high-rise buildings, bridges, tunnels, industrial facilities, infrastructure projects, precast concrete, residential construction, and various challenging or remote sites.

Concrete end hose pipes continue to revolutionize the construction industry by enabling accurate and efficient concrete placement, even in the most complex scenarios. Adhering to best practices, proper training, and regular maintenance ensures the safe and successful implementation of these hoses in diverse construction projects.