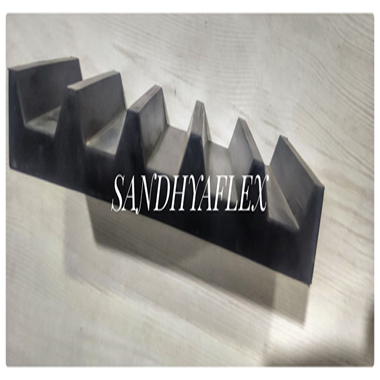

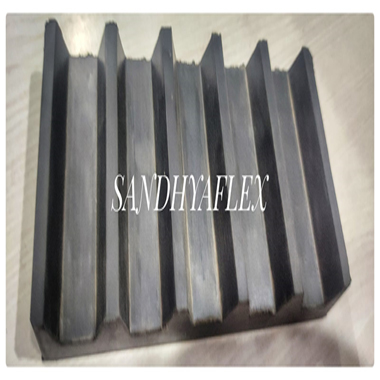

EPDM Groove Pad :

SANDHYAFLEX EPDM Groove Pad is used in RE Walls in Bridges.We are the manufacturer of EPDM Groove Pad These EPDM Groove Pad are made up of the high quality of raw material. in different shapes, sizes, lengths and finish to suit the requirement. Our developed range of grooved rubber sole plates is very effective to reduce the shocks of vibrations caused by the trains while passing through the tracks.

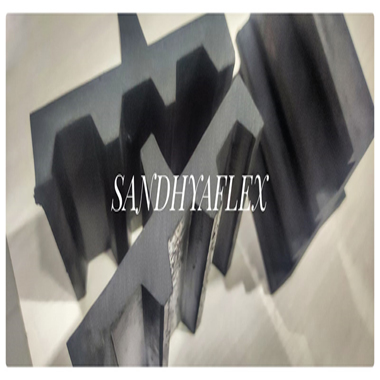

SANDHAFLEX RE Wall Pads which is also called as Rubber Pad or EPDM Elastomeric pad is used for the below To maintain Gap in RE Wall

- To avoid vibration on the bridge which absorbs the vibration

- This is avoid cracks in the structure

We provide high quality EPDM Groove Pad, also called RE Wall Panel Rubber Pad These PAD are manufactured using high grade materials (EPDM (Ethylen Propylen Dien monomer, Black Carbon Reinforcement, and Other Chemical with the aid of contemporary techniques at our advanced production unit. The Pad provide adequate support to bridges for absorbing vibrations and preventing their deformation. In addition, we offer these Elastomeric EPDM Pad at reasonable prices.

Features

- Extended durability

- Excellent flexibility under lateral load

- Easy to install

- Water Abosorption

- Reinforced Soil Wall Panel Builded RE Wall

We are one of the eminent manufacturers and suppliers of EPDM Pads. These pads are manufactured using the finest quality material, procured from reliable vendors under the observation of seasoned professionals. Offered pads are checked at our well-equipped facility on various parameters to ensure its long service life. These pads provide economical solution used to withstand loads and deformation in any direction for the construction of large-span bridges and buildings. EPDM Groove Pads are available at industry leading prices.

Application

RE Walls in Bridges.We are the manufacturer of EPDM Groove Pad These EPDM Groove Pad are made up of the high quality of raw material. in different shapes, sizes, lengths and finish to suit the requirement. Our developed range of grooved rubber sole plates is very effective to reduce the shocks of vibrations caused by the trains while passing through the tracks.

SANDHAFLEX RE Wall Pads which is also called as Rubber Pad or EPDM Elastomeric pad is used for the below To maintain Gap in RE Wall

- To avoid vibration on the bridge which absorbs the vibration

- This is avoid cracks in the structure

Benefits

Our bridge deck are composed of numerous elastomeric material laminates that is separated through steel supports. The complete bearing size and laminate thickness is as per demand of transferred load. Bearings possessing steel plates are supported should be compresses or cast vulcanizes or molded as one unit in mold below heat and pressure.

Role of the EPDM Groove Pad

RE Panel Avoide the Vibration is primarily achieved by a component called EPDM pad. This is typically made of a strong and pliable material such as Etylene Propylelen Diene Monomer. These pads are placed in between RE Wall Panel. Their primary function is to distribute superstructure loads to the substructure and allow the superstructure to undergo necessary movements in irregular environmental conditions without creating any harmful stresses that might compromise the structural integrity of the bridge. When the structural integrity of the RE Wall Paneld is compromised, the RE Wall Panel could Crack

| S No. | Properties | Test method | Specifications |

|---|---|---|---|

| Base polymer | EPDM | ||

| 1 | Hardness (Sh.A) | ASTM D2240 | 80±5 |

| 2 | Tensile Strength (MPa) min | ASTM D412 | 12 |

| 3 | Elongation@ Break (%) min | 200 | |

| 4 | Heat Ageing@ 70°C/70 Hrs | ||

| Change In Hardness, (Points), max | ATM D573 | +10 | |

| Change In Tensile (%), max | -25 | ||

| Change In Elongation (%), max | -25 | ||

| 5 | Compression Set @ 70°C/22 Hrs (%) max. | ASTM D 395 Method B | 35 |

| 6 | Resistance to Ozone,Quality Retention rating (%), min. |

ASTM D 1771 | 85 |

| 7 | Water resistance for 70Hrs/100°C, Volume Change, max. (%) |

ASTM D 471 | 10 |

| 8 | Colour | Black | |

| 9 | Density | 1.19±0.03 | |

| 10 | Tear Strength daN/cm | 38 | |

| 11 | Max. Ash Content | <5% |

| Sr.No | Dimension | Groove | Weight/Nos | Rate/Nos |

|---|---|---|---|---|

| 1 | 150x70x22mm | 6 | 210gram | 40 |

| 2 | 100x85x20 | 4G/aG | 190 gram | 30 |

| 3 | 100x85x20 | 4 | 180g | 30 |

| 4 | 130x85x20mm | 5G/1G | 220g | 35 |

| 5 | 130x85x20mm | 5 | 210 | 35 |