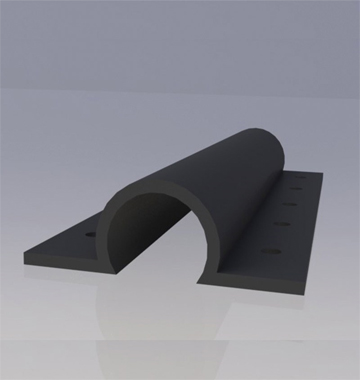

Omega Seal Expansion Joint :

Main components are Omega Seals, Steel Plates and Nut & Bolts.

- Omega Seal Expansion Joint for Railway Bridges.

- Surface shall be 1% slope in order to get water drained as shown in figure.

- Steel bolt shall be inserted into the recess made in the deck and to be filled with M 35 grade concrete.

- Cap seal to be positioned on both sides of the decks such a manner that the omega shape covers the gap and the plain surface are perfectly sat on the deck slab.

- Galvanized steel plate(80 X 80mm) having oblong hole (40 X 20mm) to be placed on the plain surface of the seals at both sides such a manner the bolt is inserted through the oblong hole. Seal also to be punched with a hole suiting to oblong hole of the steel plate to enable to get inserted through the bolt.

- Nut to be tightened on every bolt properly and tack welded to ensure the locking.

- On completion of installation, every aspects to be checked for proper installation.

- Wearing coat shall be done with proper care without disturbing the seal.

STEEL PLATE:

- It is hot dip galvanized steel plate of 80mm wide x 8mm thickness with oblong holes of 40 x 20mm in every one meter.

- RIGID BOLT:

- The rigid bolt will be anchored to the both decks by reinforced concrete, in every one meter, all along. After installation

- elastomeric seal and steel plate inserting into the bolts anchored in the decks, the nut to be tightened well and tack

- Welded. The dimension of the bolt will be 16mm dia @ 400c/c.

- It is made out of chloroprene elastomer to the shape Omega,by compression moulding process. The seal with omega

- shaped design will be cast as single unit in a mould and vulcanized under uniform heat and pressure. The mould used for

- manufacturing such seal will be free from defects and will have polished surfaces in order to get the elastomeric seals free

- From any surface blemishes.

- Chloroprene elastomer is used to manufacture such seals and they are with low crystallization rates and adequate shelf

- Life. Generally Neoprene WRT, Bayprene 110, Skyprene B5 and Denka S 40V are used as raw material of Chloroprene

- Elastomer.

THE PHYSICAL PROPERTIES OF THE ELASTOMERIC SEAL WILL BE AS FOLLOWS:

- Hardness: 63 (+/-) 5 in shore A scale

- Tensile strength: 17Mpa Minimum

- Elongation at break: 400% Minimum

- Compression set: 35% Maximum

- AFTER ACCELERATED AGEING:

- 28. - Change in hardness: + 15 Maximum

- 29. - Change in tensile strength: - 15% Maximum

- 30. Change in elongation: - 40% Maximum.