Discharge Hose

Cement Feeding Rubber Hose (HEAVY DUTY) :

Sandhya Flex is an expert in producing sturdy cement hoses that are customized for a range of construction uses. The seamless rubber blend of synthetic and natural rubber compounds used to make the lining of these hoses provides outstanding durability and resistance to abrasion. High-strength natural or synthetic yarns impregnated with rubber piles make up the reinforcement, which adds stability and strength. A weather- and abrasion-resistant rubber compound cover further reinforces the hose and provides protection from inclement weather.

A copper wire strand inserted into the hose also guarantees electrical continuity along its entire length. Sandhya Flex cement hoses are made to endure the harsh conditions of building sites, offering flexibility and user-friendliness along with dependable performance. Customisation possibilities help customers achieve project requirements that are unique to them. Sandhya Flex guarantees that every hose satisfies industry standards and requirements, providing technical assistance and after-sales service to maximise performance. The company is dedicated to quality and client happiness.

Application of Cement Hose: Cement Feeding Rubber Hose is used for spraying cement grout at irrigation projects, buildings, dams, sites, dams, bridges and roads in hilly terrains.

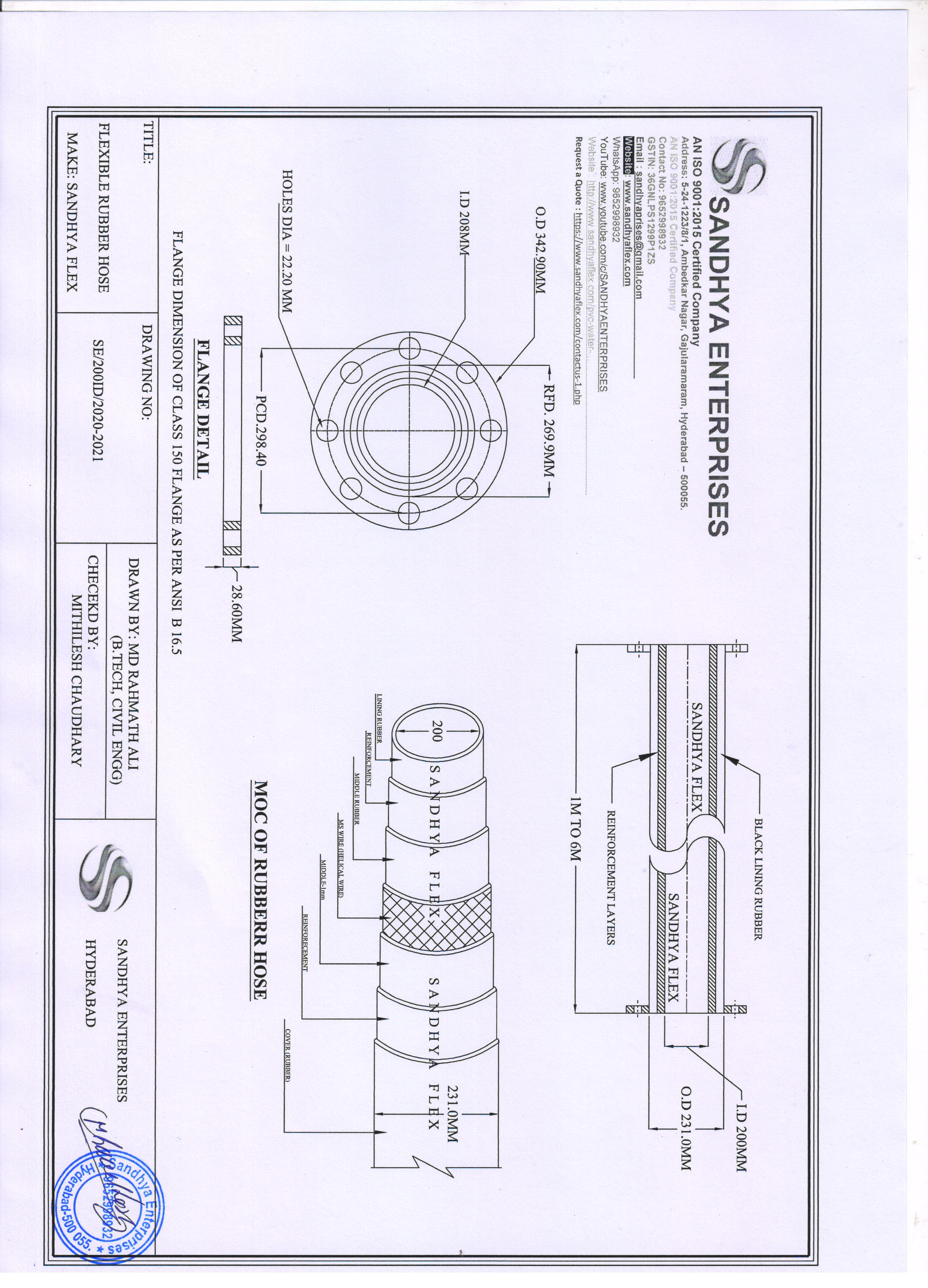

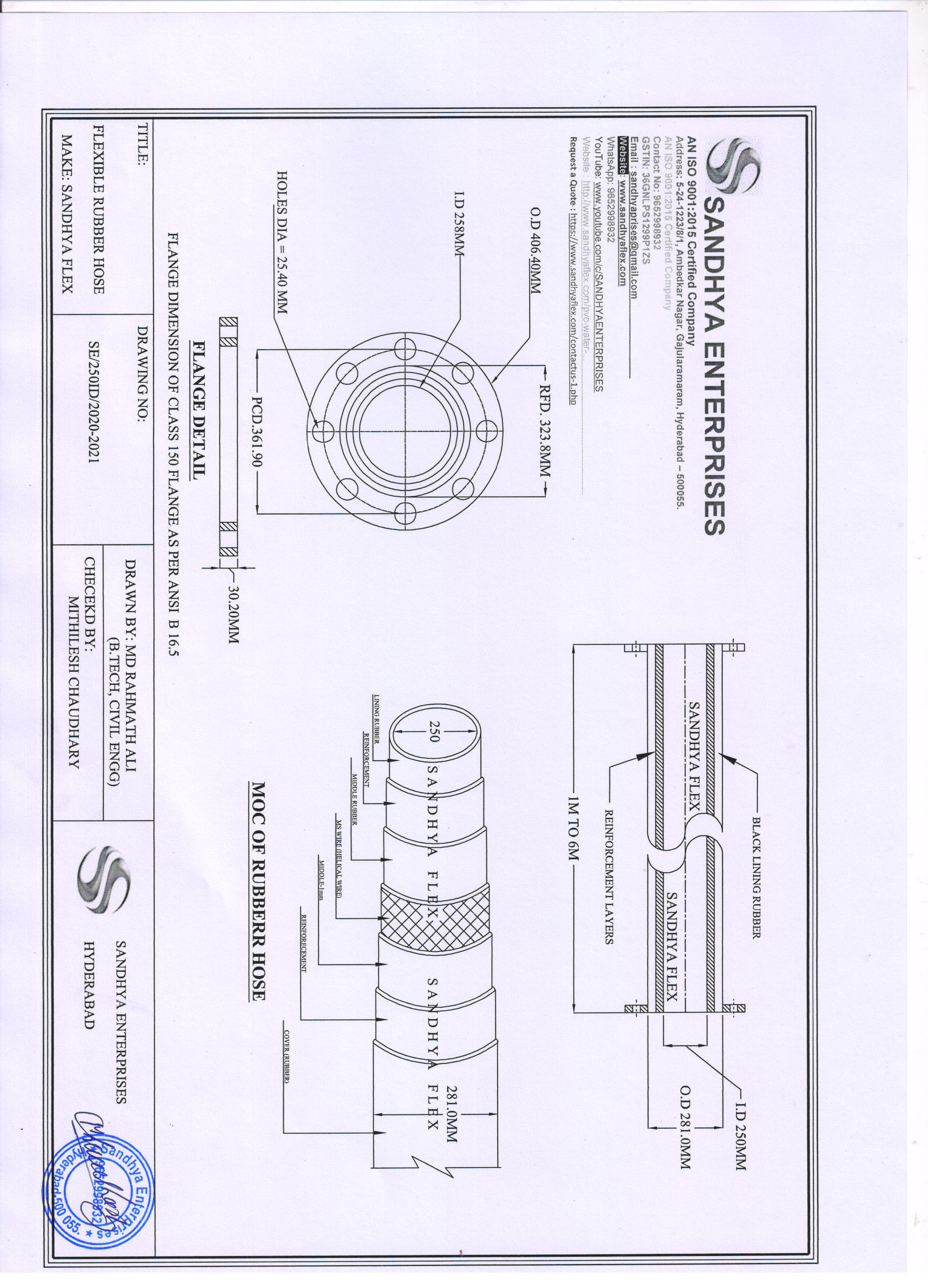

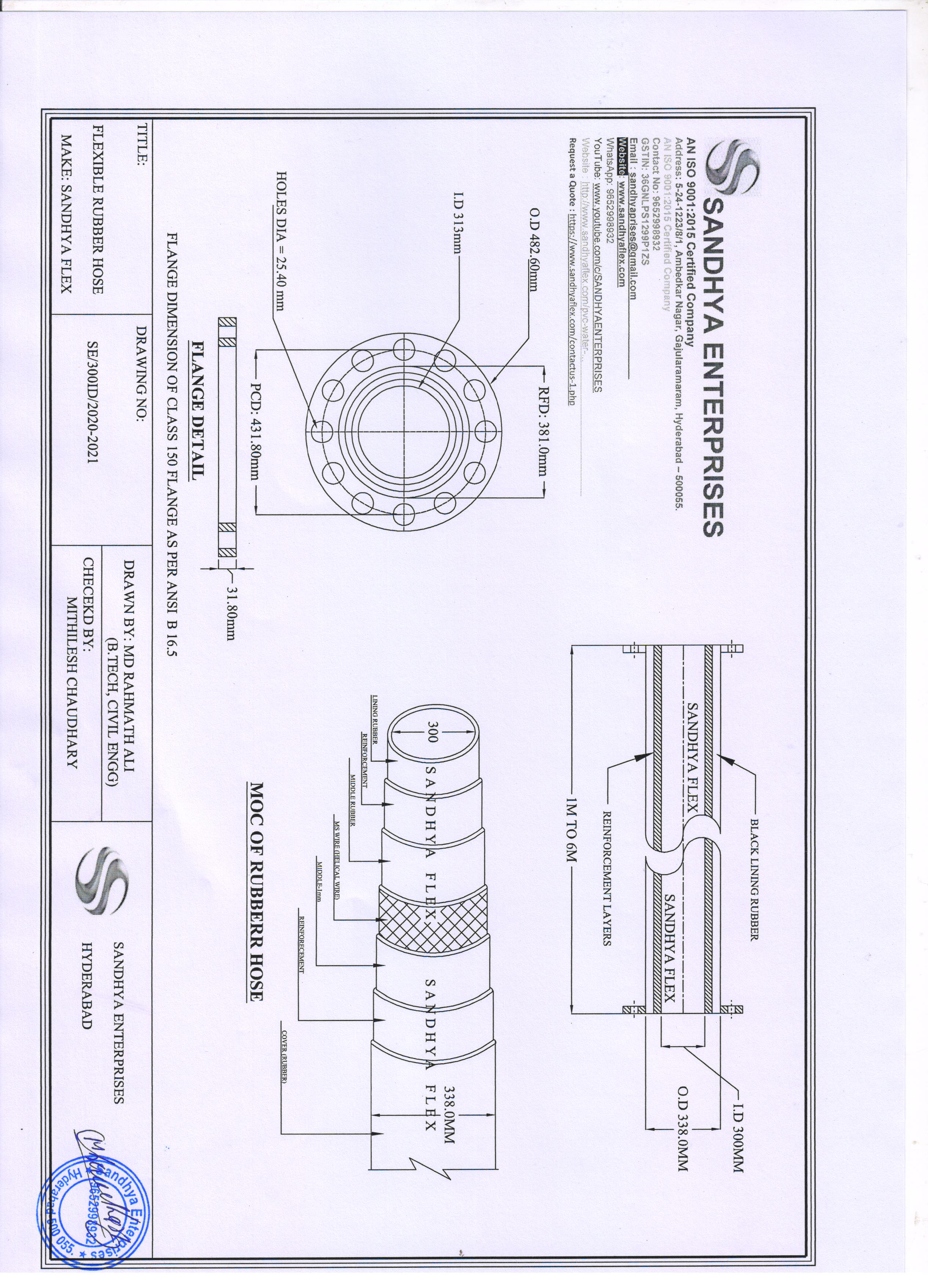

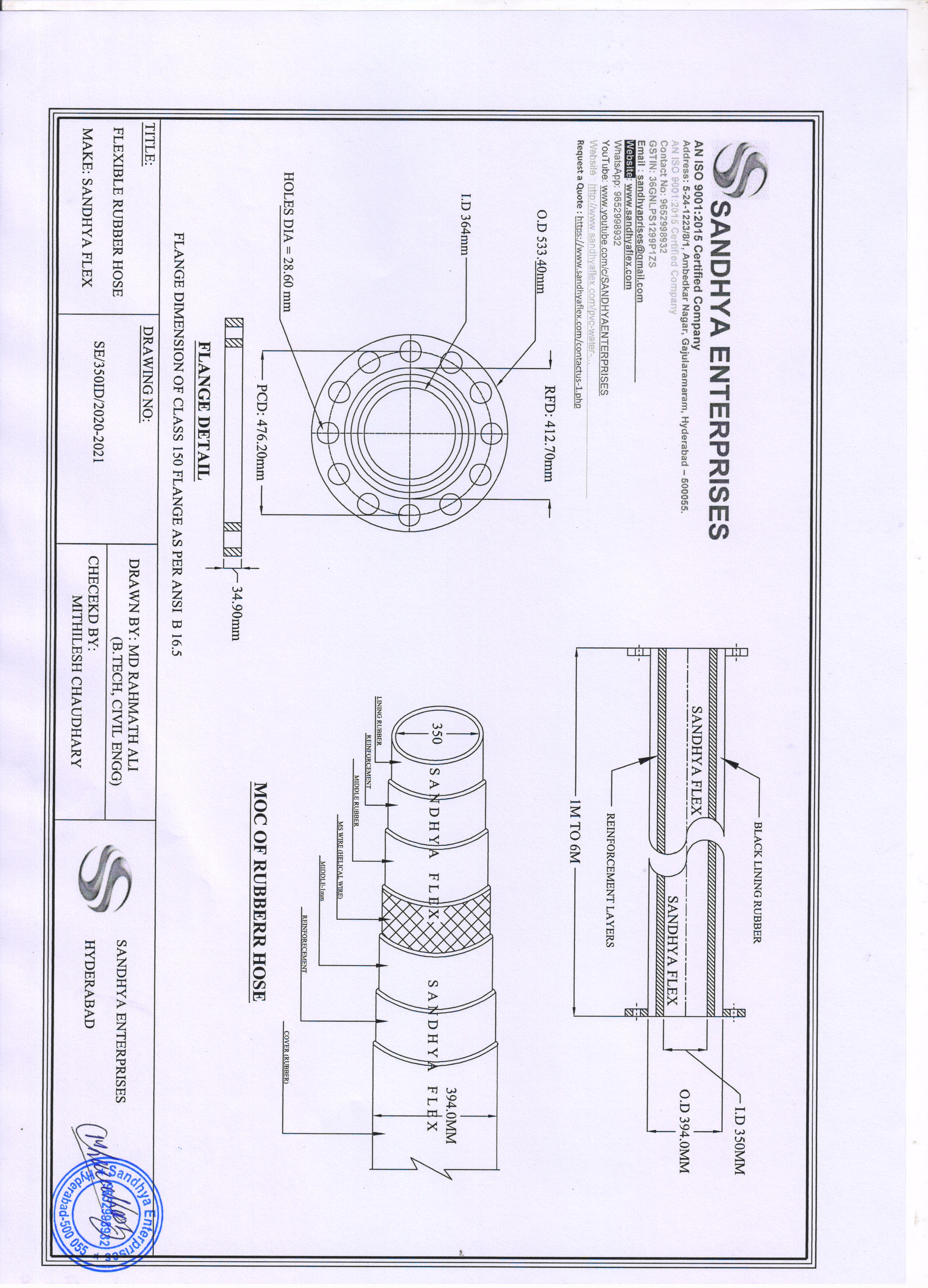

Construction:

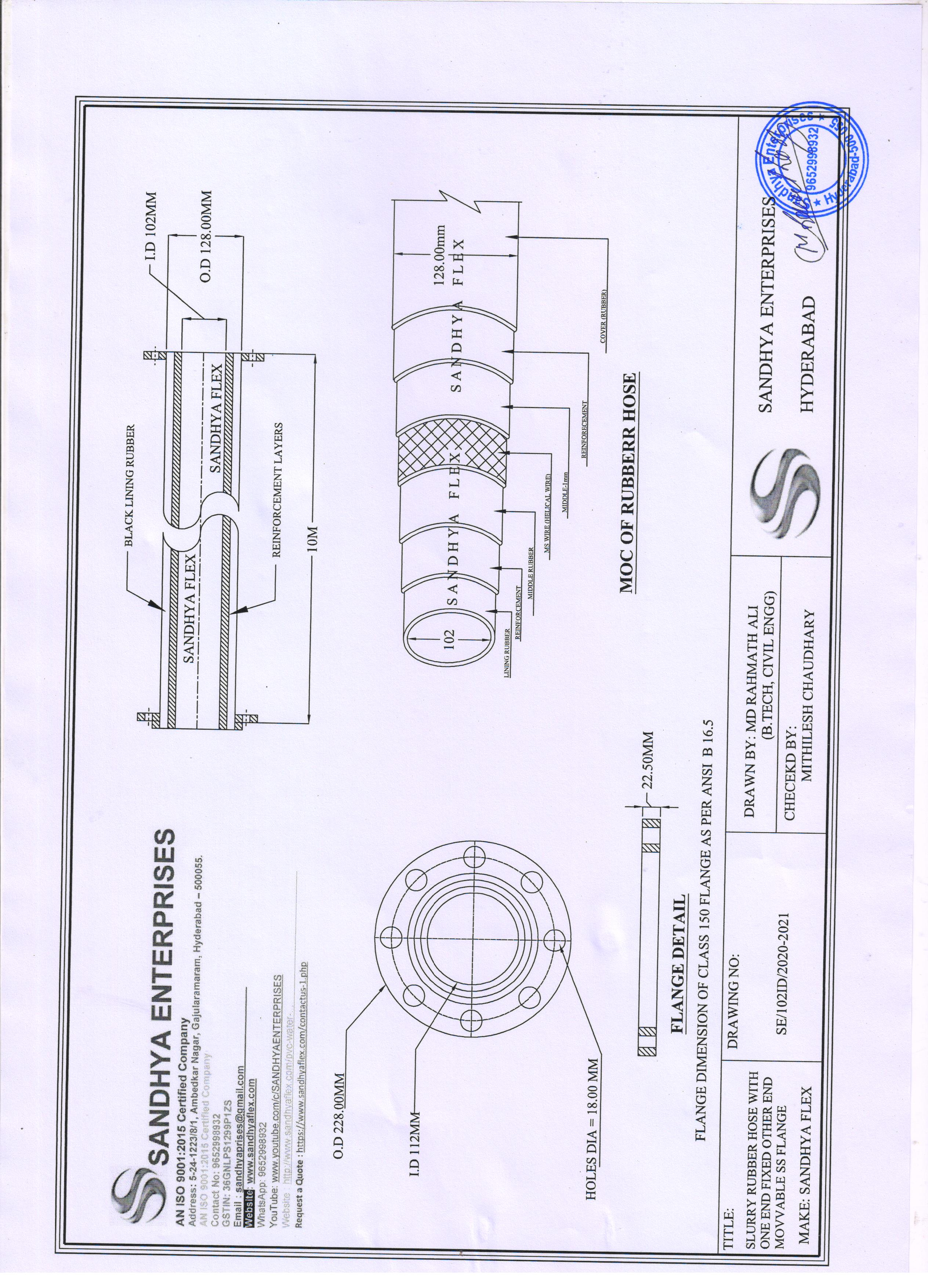

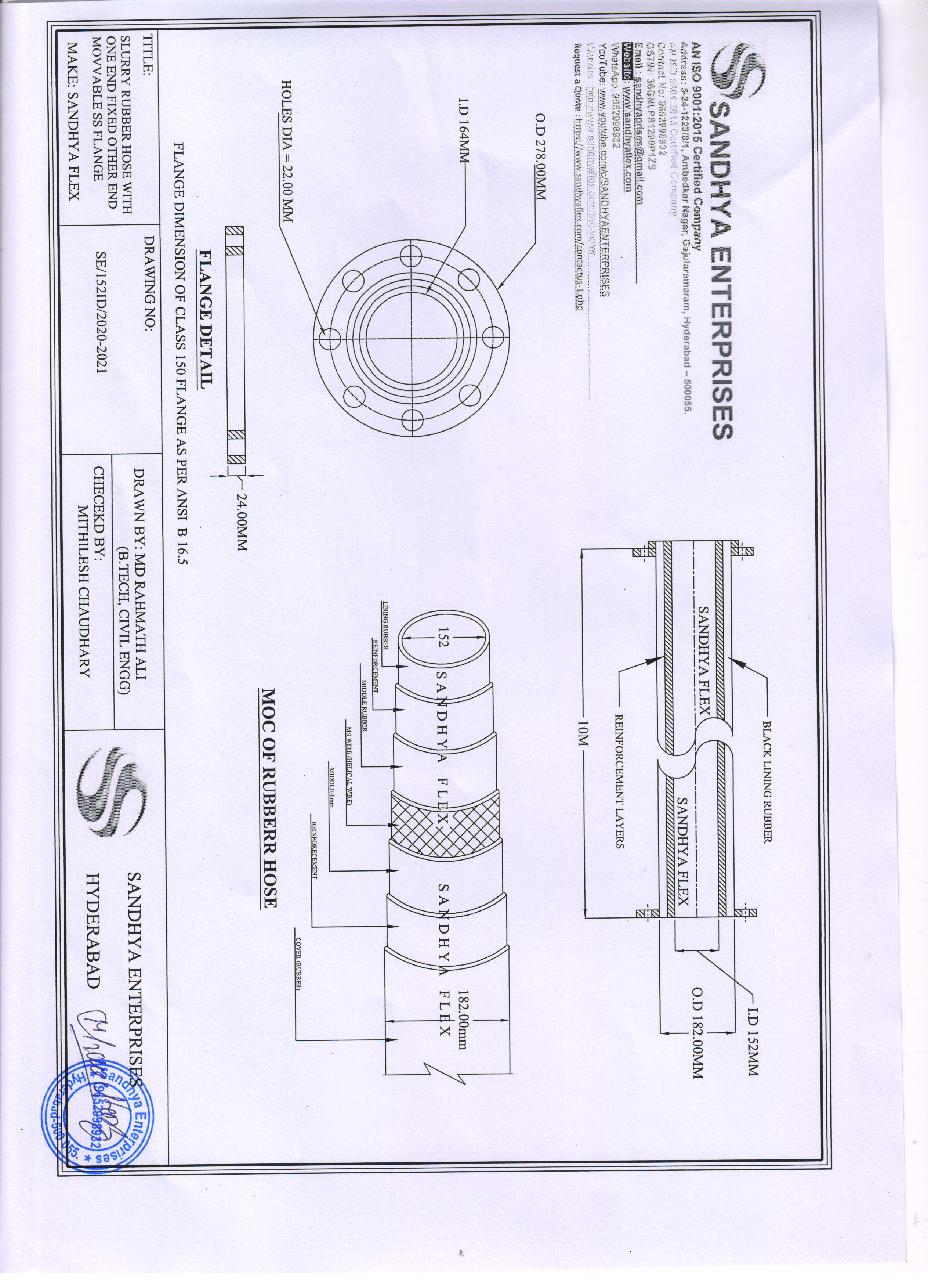

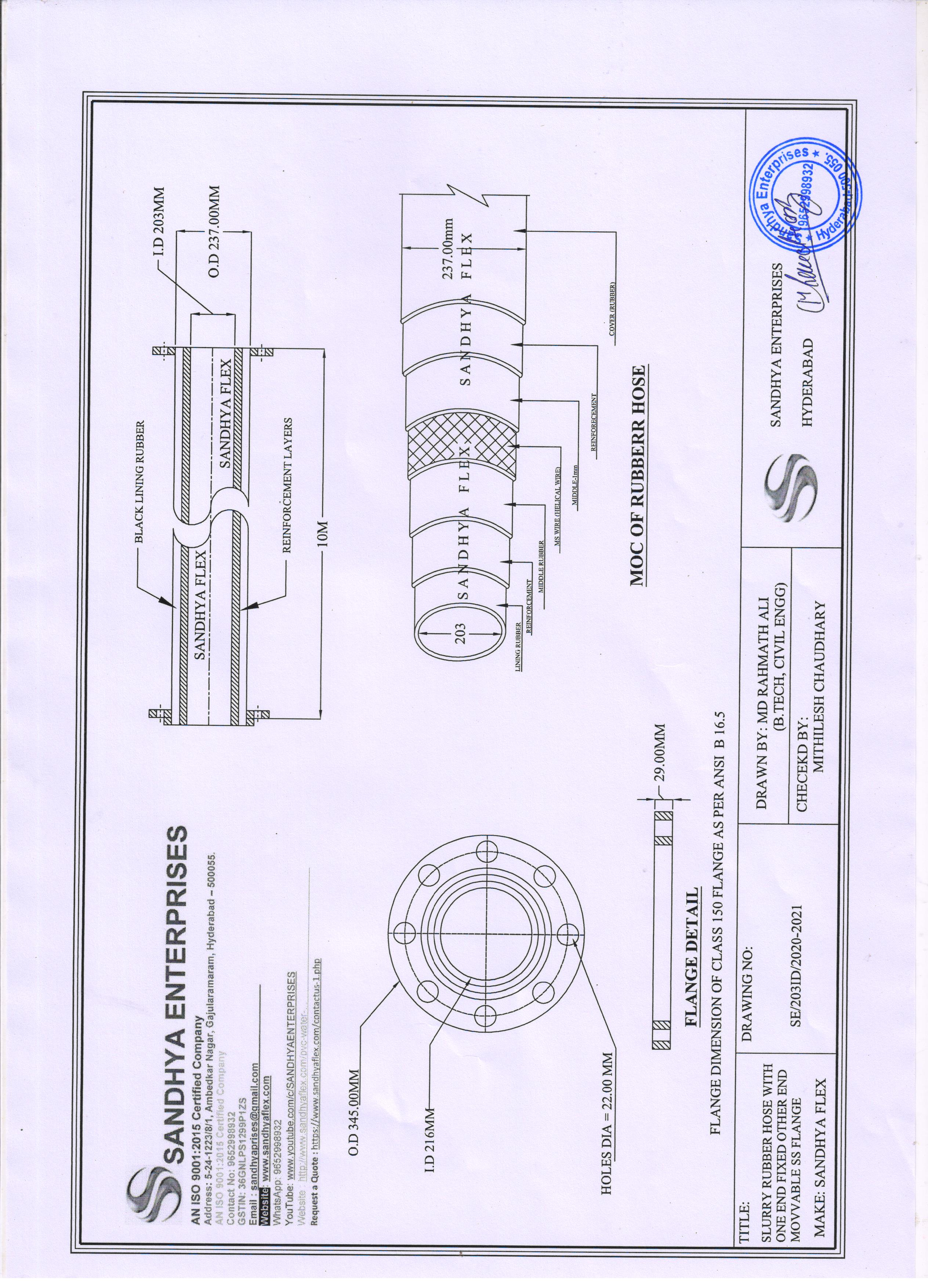

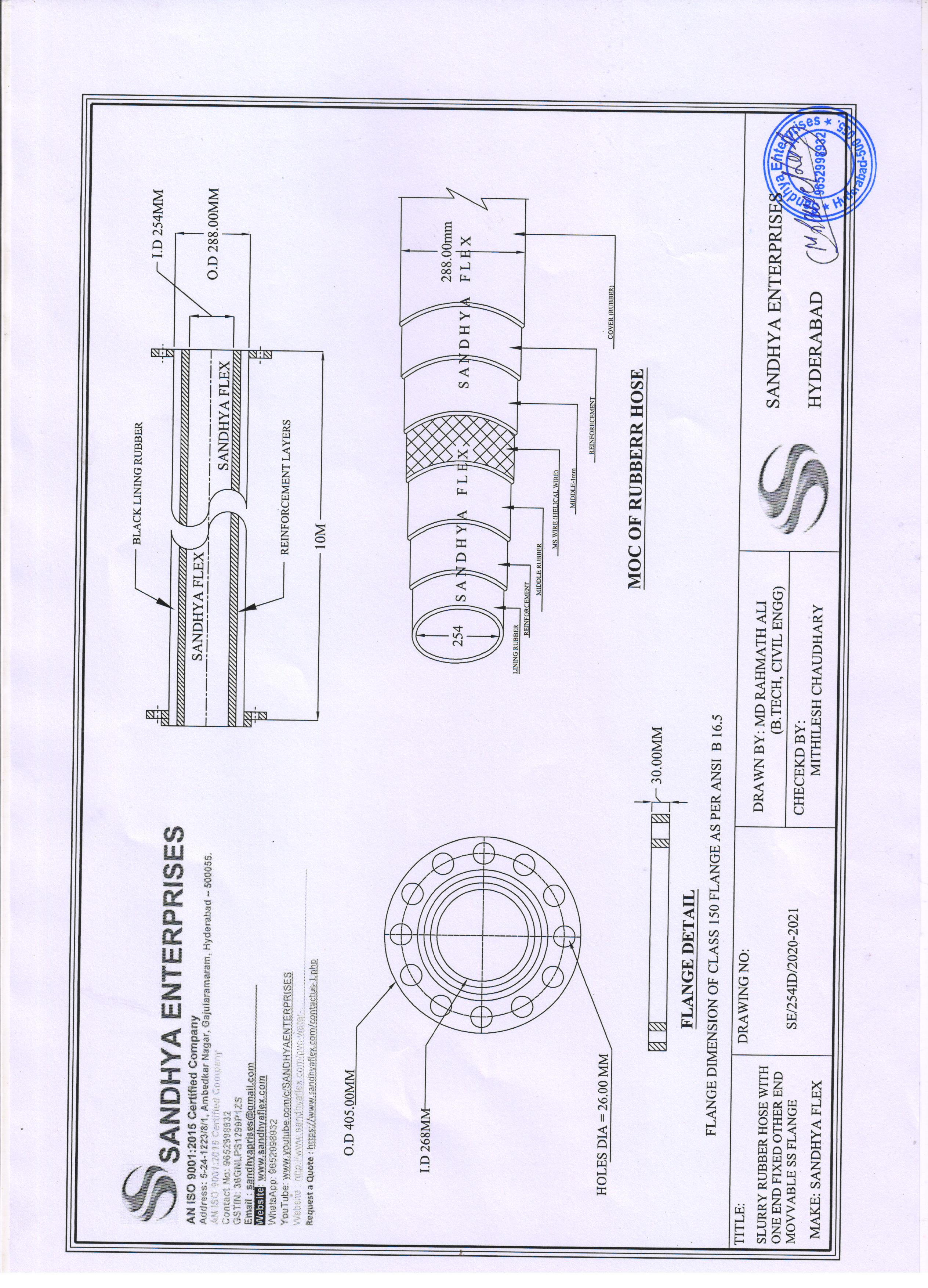

Lining: This is a natural, synthetic, and blended rubber compound tube that is unusually thick, homogeneous, and seamless. It delivers excellent abrasion resistance without air blisters, porosity, or other flaws.

Reinforcement: Rubber piles impregnated woven textiles or braided high-strength natural or synthetic yarns

Cover: This rubber compound is acceptable and has a cloth-marked surface that makes it resistant to weather and abrasions.

Electrical Bonding: To ensure electrical continuity along the entire length of the hose, a stand of copper wire is placed in the reinforcing plies.

Specifications

Compliant with IS: Our cement hoses, which adhere to IS: 13071-1991 standards, have strong features made to withstand the demanding needs of the construction sector.

Core: The hose's black, abrasion-resistant core, which is made of a sturdy mixture of natural and synthetic rubber, ensures longevity and dependability under harsh conditions.

Reinforcement: Our hoses are reinforced with high-tensile synthetic textile cords, which give them exceptional strength and stability. This allows for the effective placement of sand, plaster, and cement during building projects.

Cover: Made of synthetic rubber in black, our hoses are designed to withstand ozone, weathering, and abrasion, giving them extra endurance and protection in harsh environments.

Application: Our hoses are designed to provide outstanding performance and dependability, making them perfect for precisely placing sand, cement, and plaster in construction applications.

- Operating Bar: 10 Bar (10 kg/cm³)

- Proof pressure equal to 1.5 W.P.

- Peak Pressure: Three times W.P

- Two or three galvanised wire helices embedded in layers of rubber compounds serve as reinforcement.

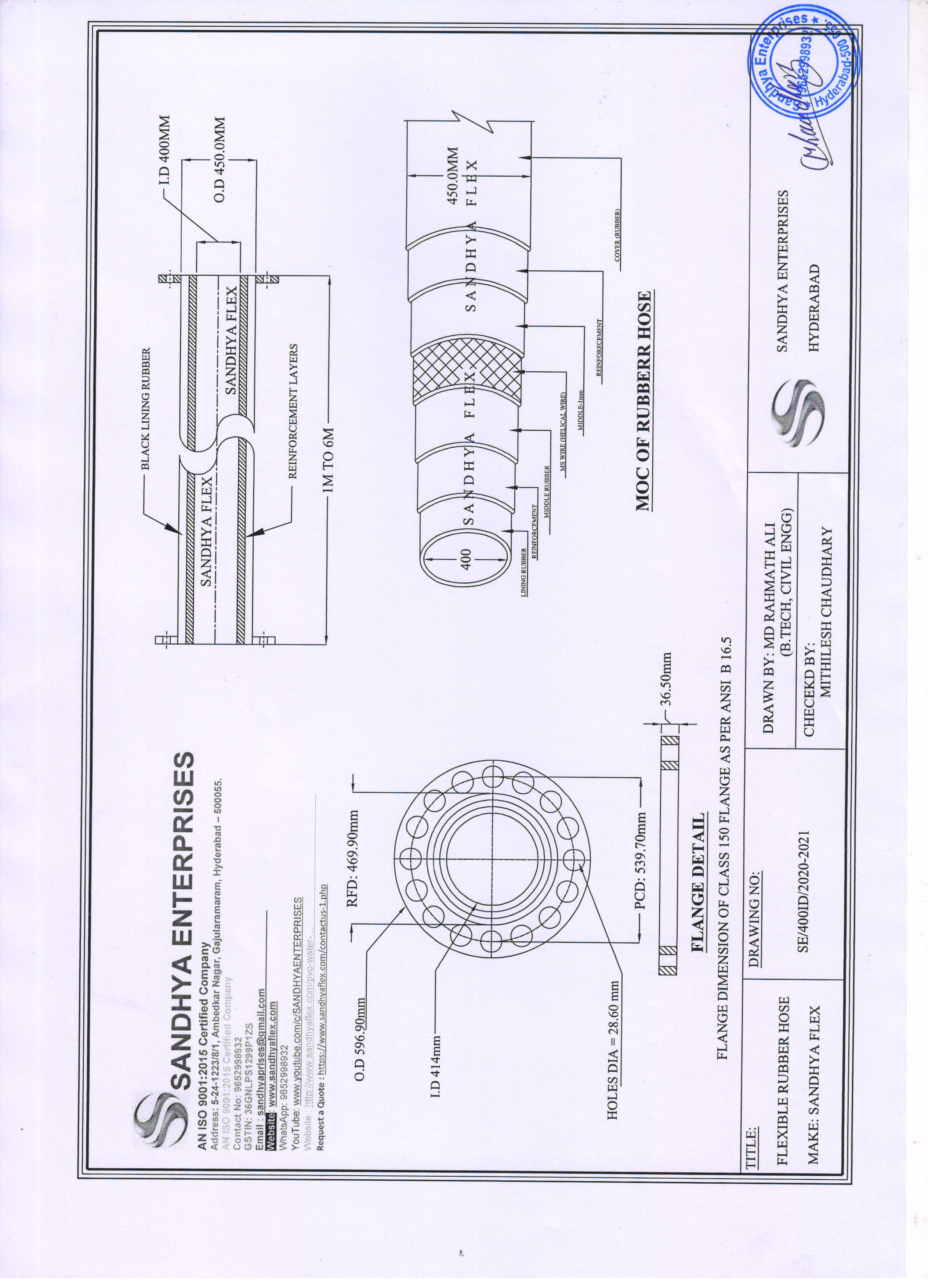

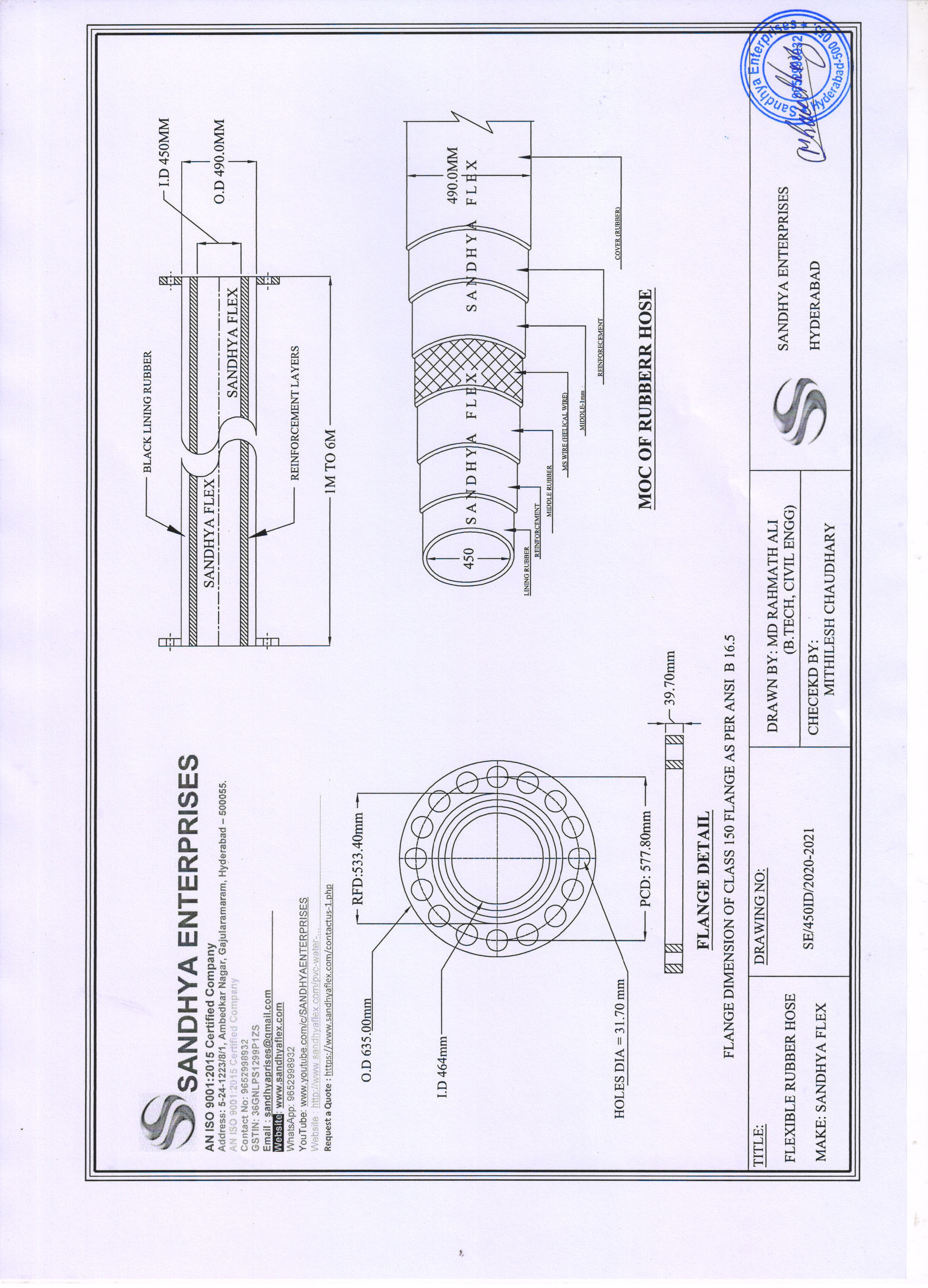

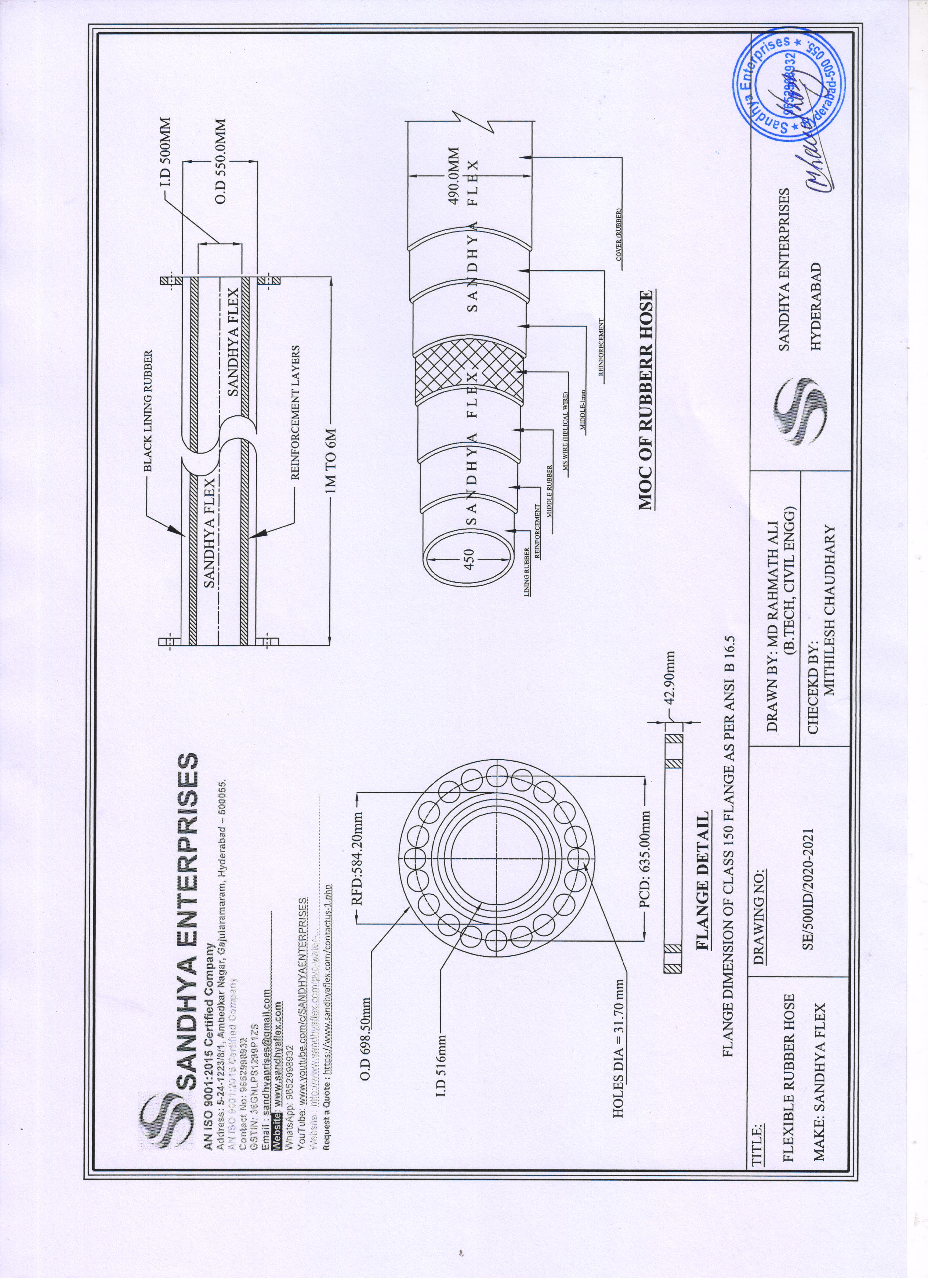

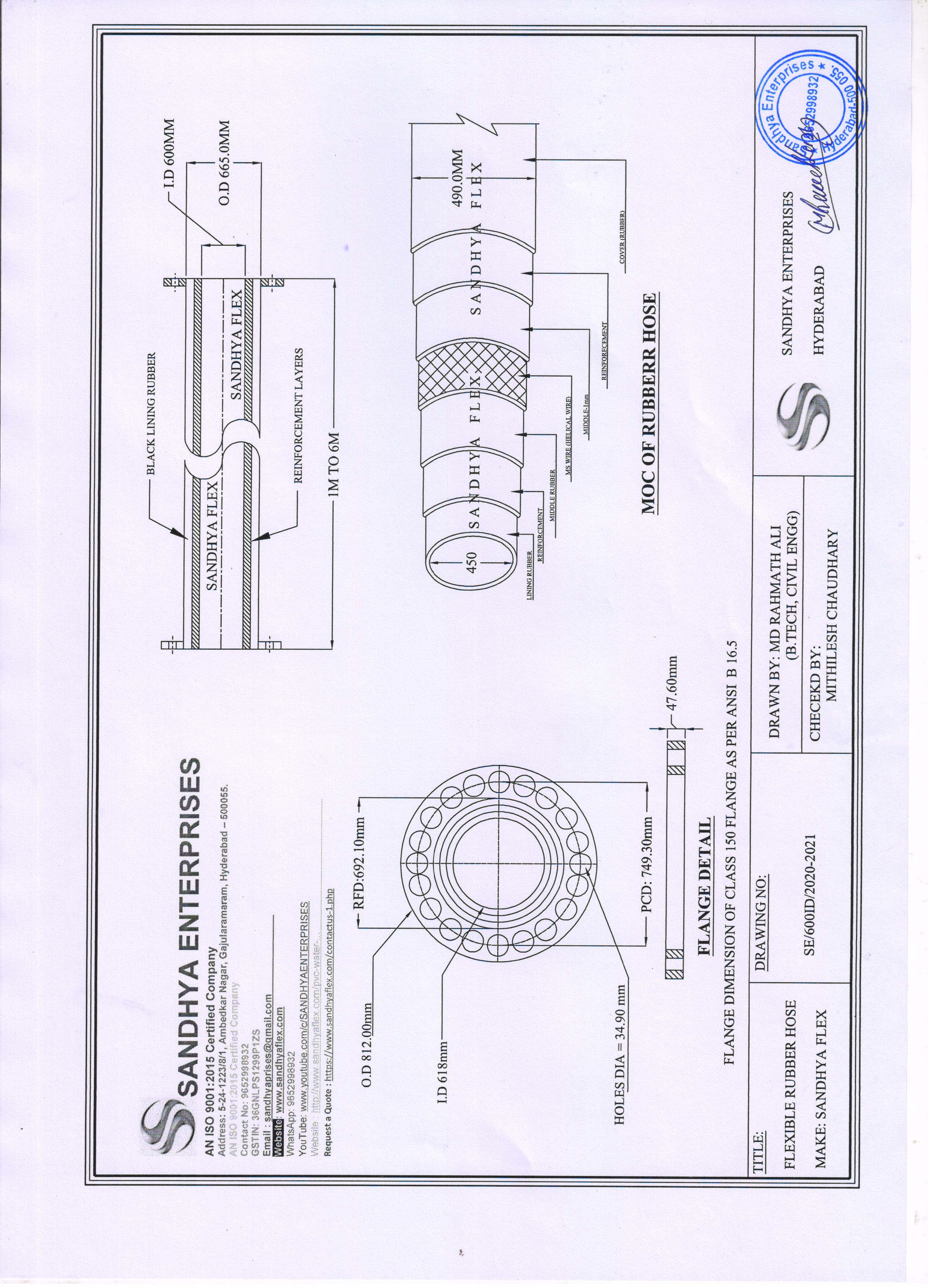

- End Connection: Type of Built-in Flange

- Maximum Length: 15 Metres to 5 Inches

- Use: Sand and gravel, mud slurry, concrete slurry, mining particles, etc. suction and discharge.

- Bore: Smooth Bore Curvature Radius: 10 times the inner Hose Vacuum Diameter: Minimum 700 mmHg (0.9 Bar)

- Material for lining: NR/SBR unable to be penetrated by corrosive and abrasive products 50 to 60 Shore A hardness.

- Carcass: Steel Helix Coated Embedded in Synthetic Textile Plies Content: Adaptability to Adverse and Severe Weather

- Temperature range: -1°C to 100°C

| S.No | Description | Max Length |

|---|---|---|

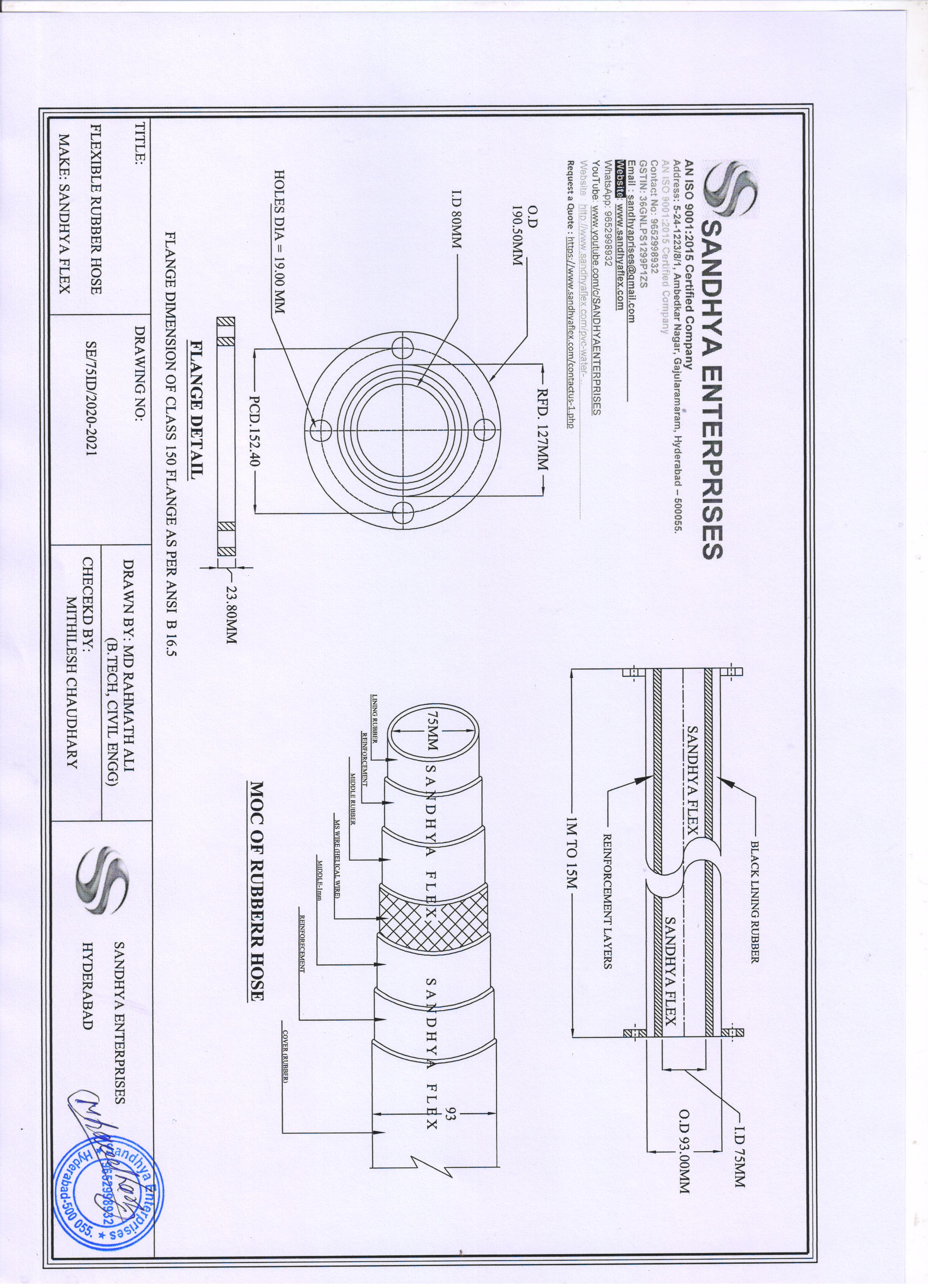

| 1 | 3” (75mm)ID x 5Mtr (LG) with Both End MS Flange as per ASA 150# | 15 Mtr |

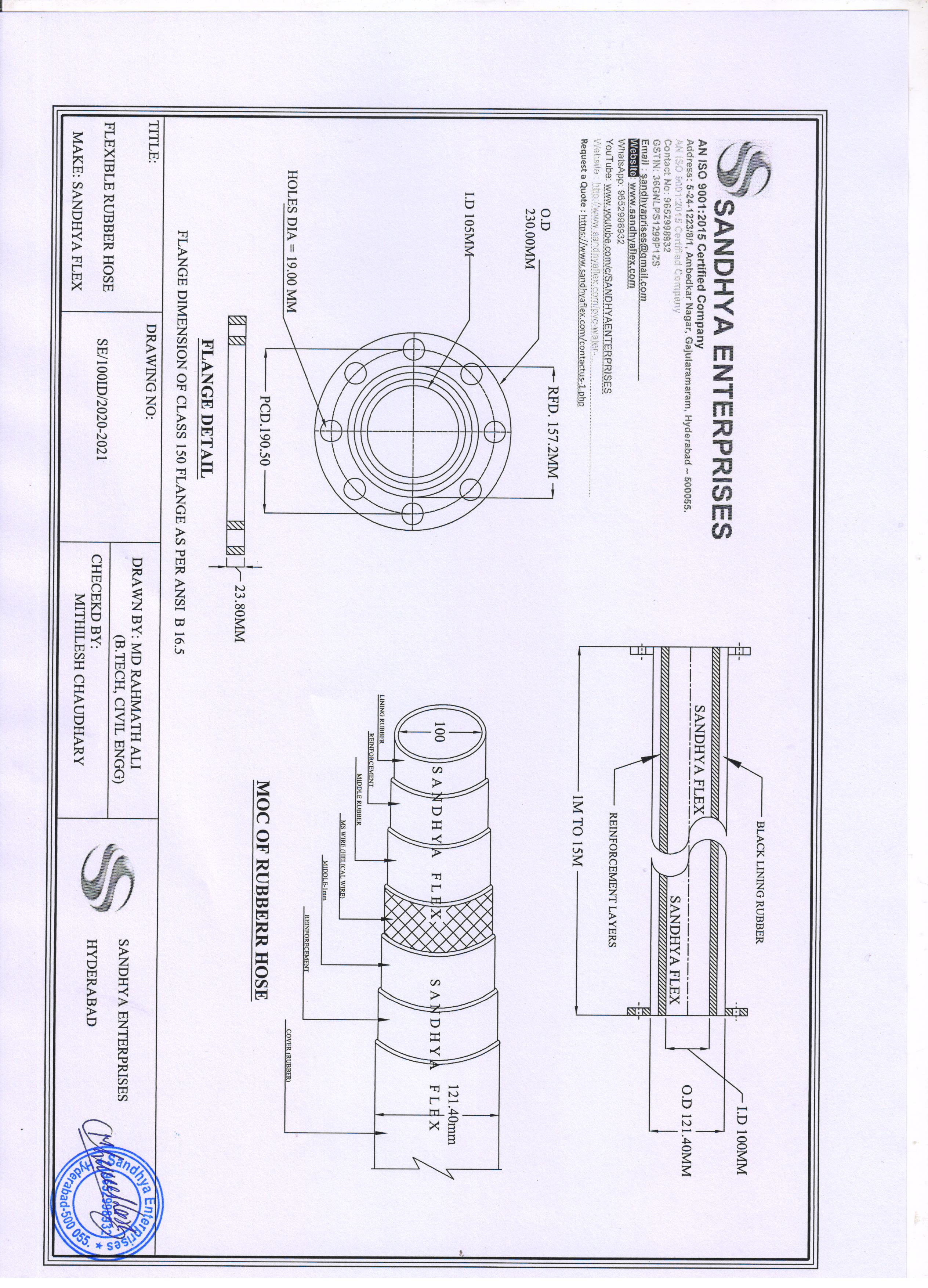

| 2 | 4” (100mm)ID x 5Mtr (LG) with Both End MS Flange as per ASA 150# | 15 Mtr |

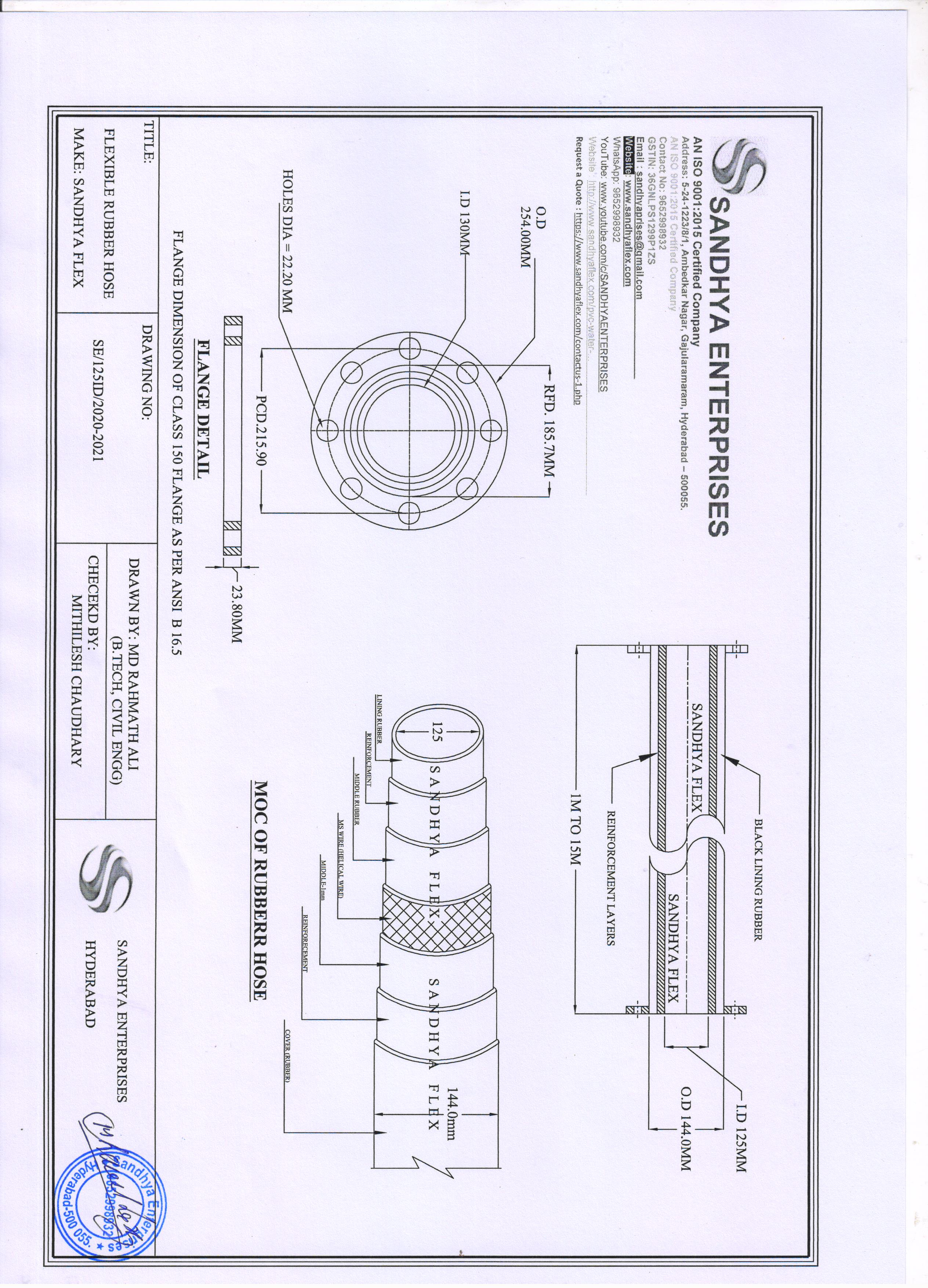

| 3 | 5” (125mm)ID x 5Mtr (LG) with Both End MS Flange as per ASA 150# | 15 Mtr |

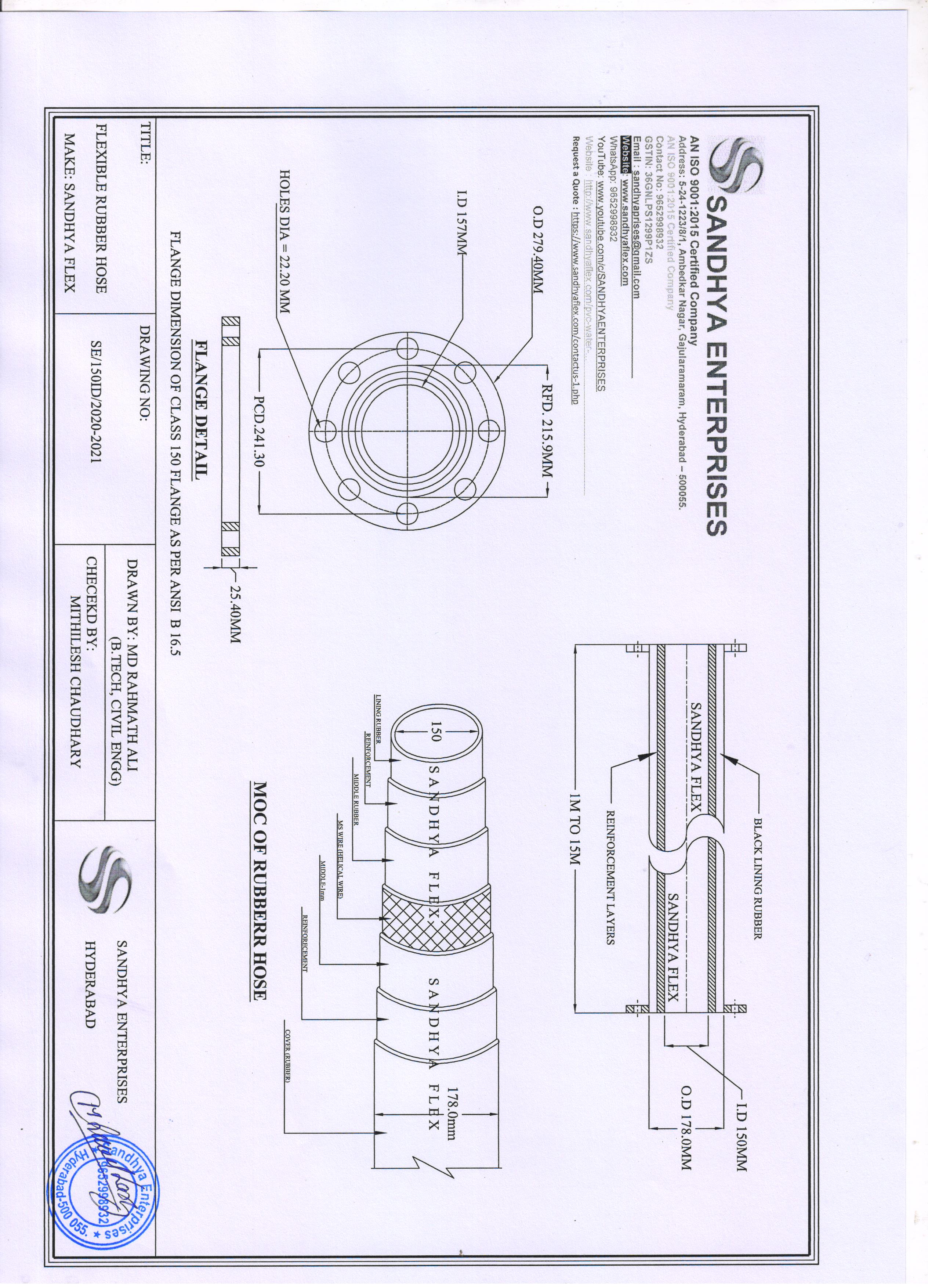

| 4 | 6” (150mm)ID x 5Mtr (LG) with Both End MS Flange as per ASA 150# | 15 Mtr |

| 5 | 8” (200mm)ID x 5Mtr (LG) with Both End MS Flange as per ASA 150# | 06 Mtr |

| 6 | 10” (250mm)ID x 5Mtr (LG) with Both End MS Flange as per ASA 150# | 06 Mtr |

| 7 | 12” (300mm)ID x 5Mtr (LG) with Both End MS Flange as per ASA 150# | 06 Mtr |

| 8 | 14” (300mm)ID x 5Mtr (LG) with Both End MS Flange as per ASA 150# | 05 Mtr |

| 9 | 16” (300mm)ID x 5Mtr (LG) with Both End MS Flange as per ASA 150# | 05 Mtr |