Discharge Hose

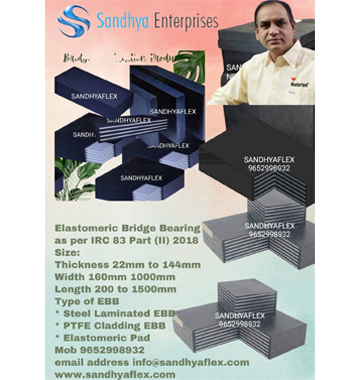

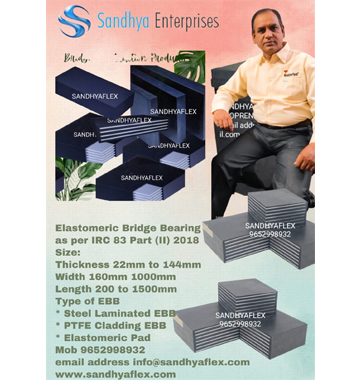

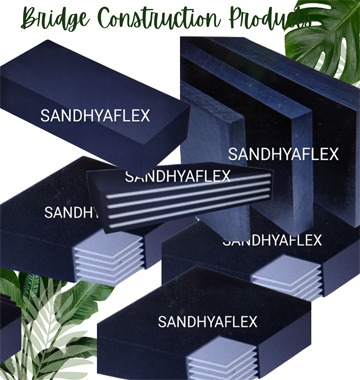

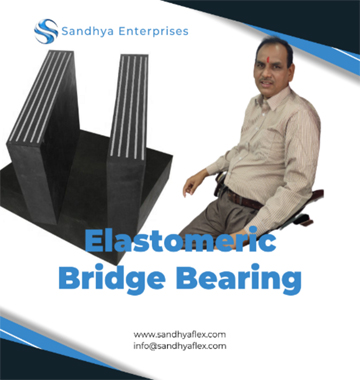

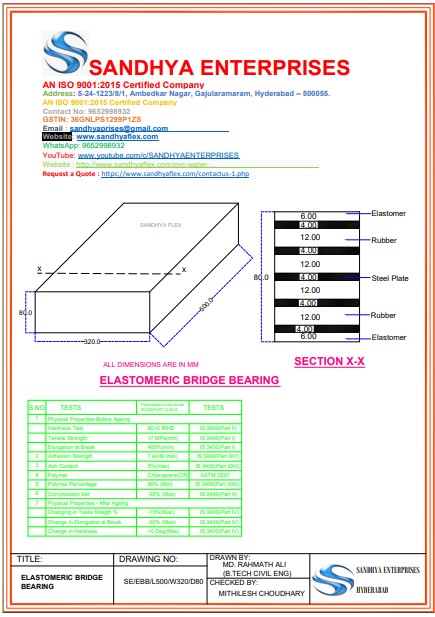

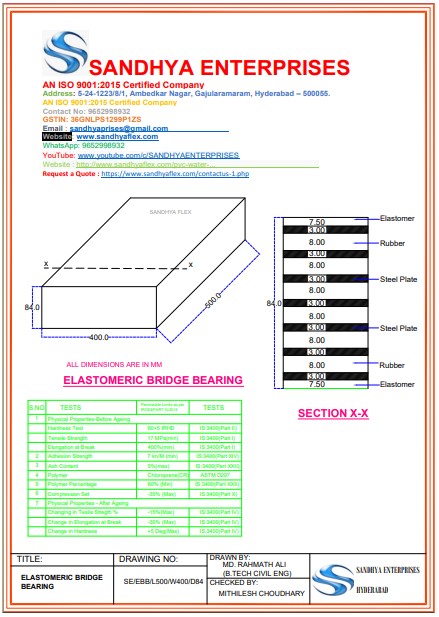

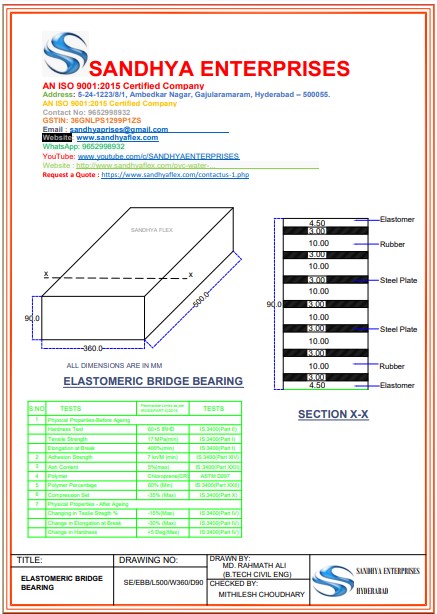

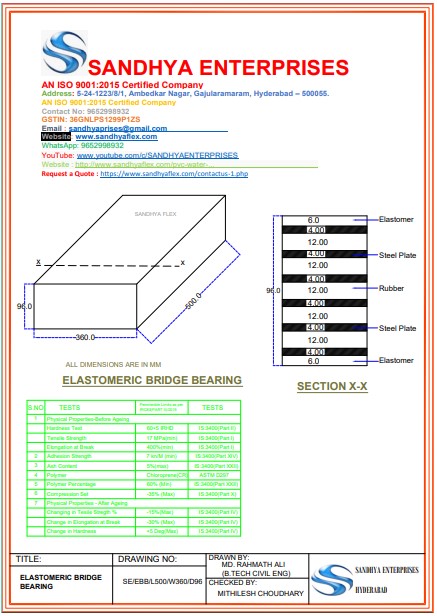

Elastomeric Bridge Bearing :

Offering the finest Elastomeric Bridge Bearing, Sandhya Flex takes pleasure as a leading manufacturer of the products. We have segregated our infrastructure into several units with one of them as packaging unit. Here we meticulously pack our Elastomeric Bridge Bearing to ensure safe and secure deliverables. For the safe storage of the manufactured products, we have installed our facility equipped with all the modern amenities for absolute quality satisfaction.

The features of the elastomeric bridge bearing involve a strong design, simple installation and high quality. Also, it allows movement in all the directions you desire. Moreover, it finds it application in bridges, auditoriums, buildings and stadiums among others. They have exceptional tensile strength along with good elongation strength.

They are easy to install for various applications. Above all, they require less maintenance as well. They are precisely manufactured by specialists and experts as per the national and international norms and standards. Also, we use premium quality raw material to manufacture these elastomeric bridge bearing which are sourced from reliable vendors. Further, we assure the best quality, superior performing, durable and energy-efficient elastomeric bridge bearing which you can get from Sandhya Flex at competitive prices in the market.

Elastomeric Bridge Bearing Features :

- Strong design

- Simple installation

- High quality

Use : Allows movement in any direction

Elastomeric Bridge Bearing Applications :

- Bridges

- Buildings

- Auditoriums

- Stadiums etc.

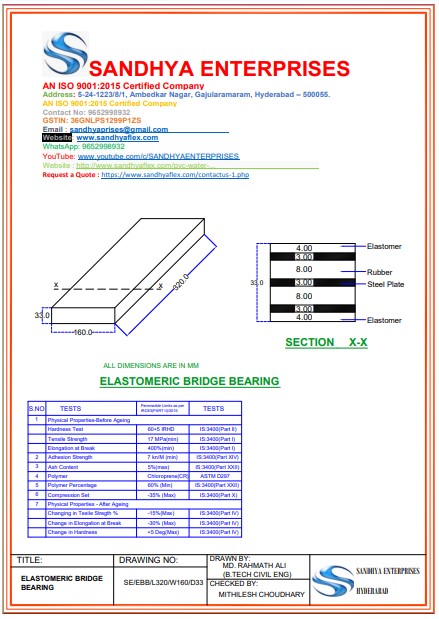

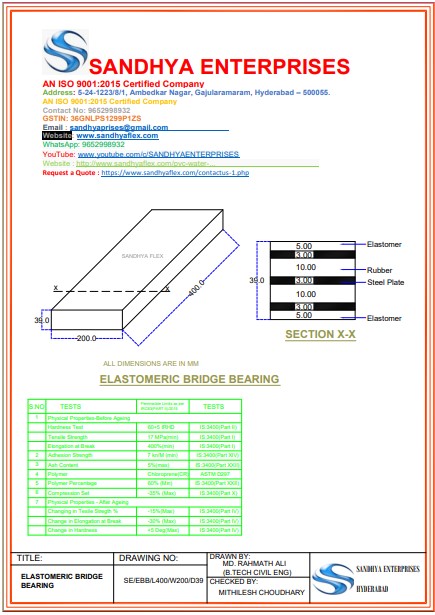

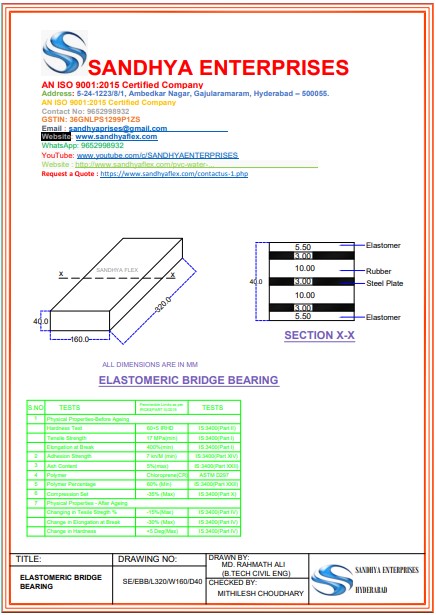

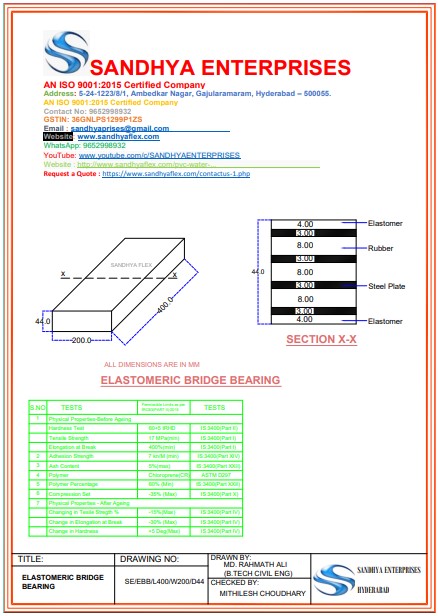

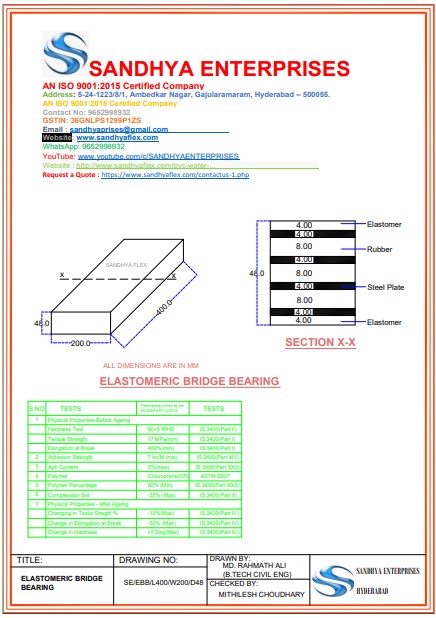

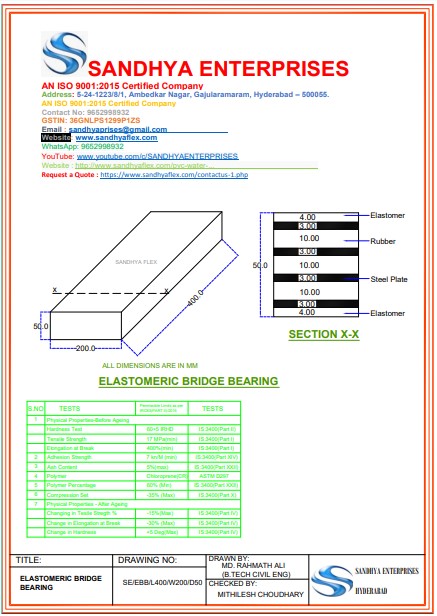

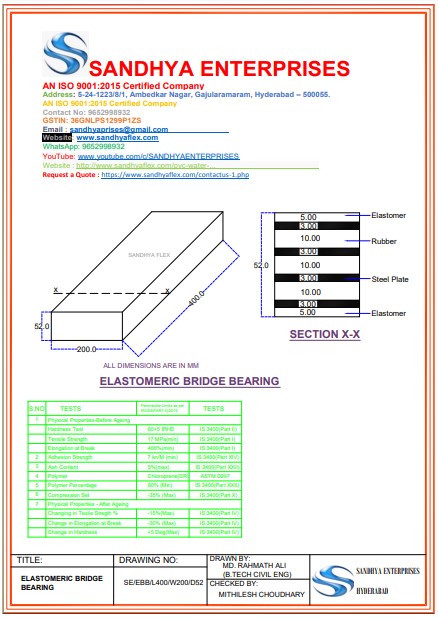

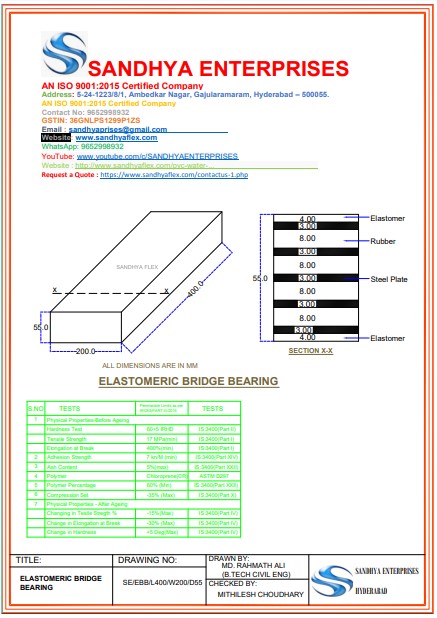

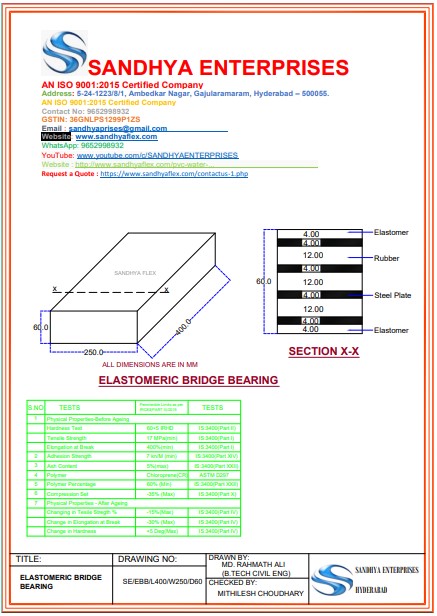

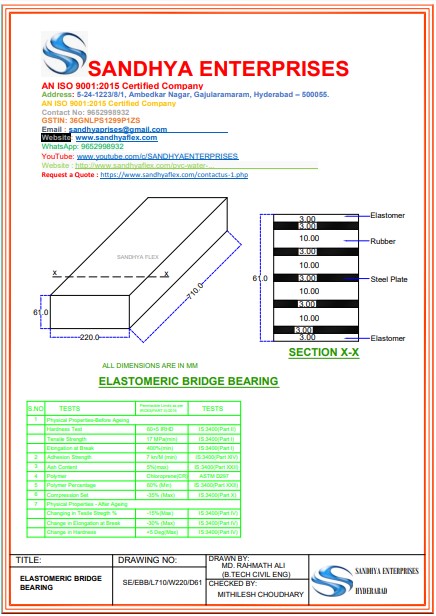

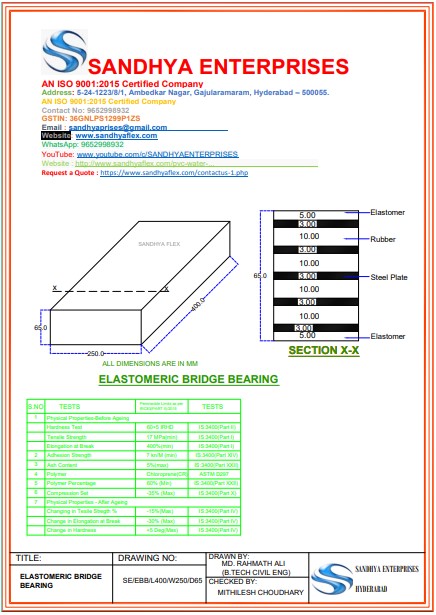

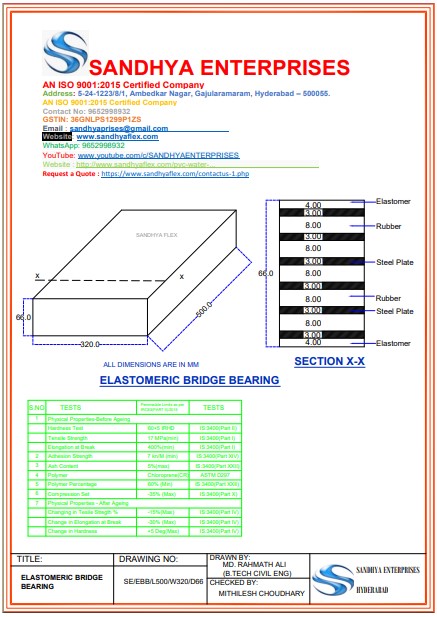

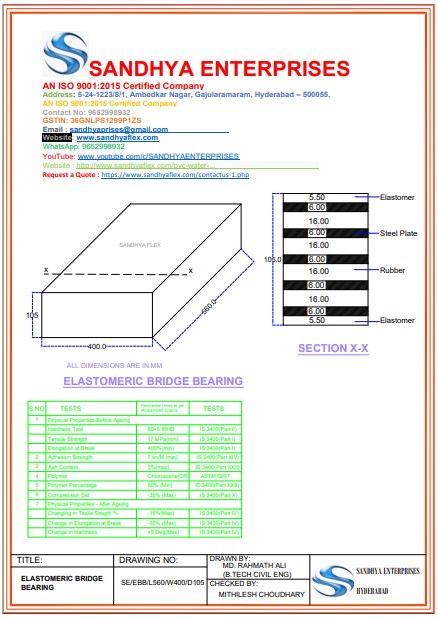

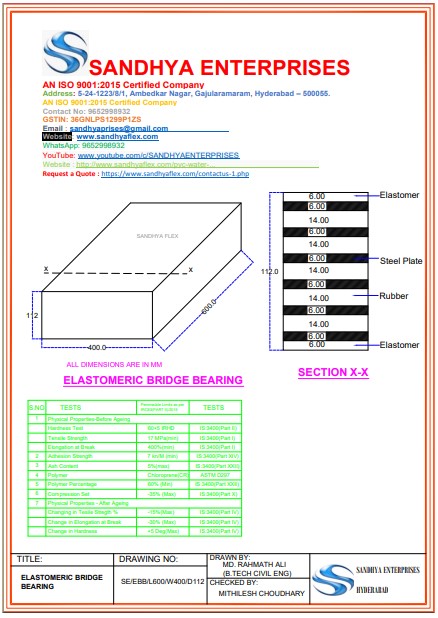

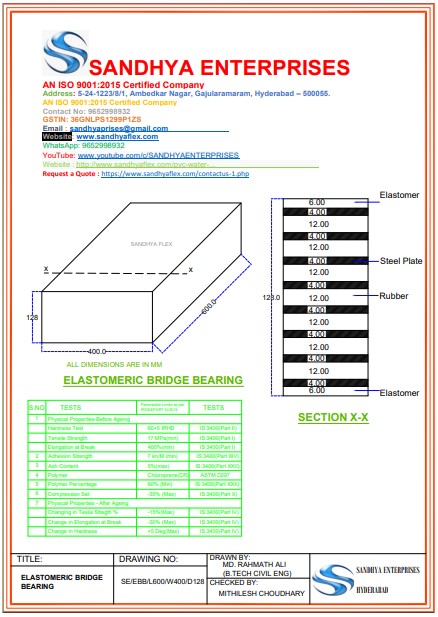

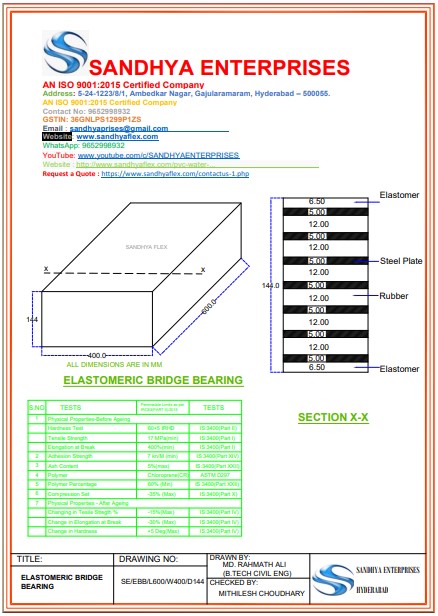

Elastomeric Bridge Bearing Technical Details :

| Sr No. | Test | Unit | Specification and Testing Method | Specimens |

|---|---|---|---|---|

| 1 | Hardness | IRHD | IS: 3400 (Part II) Cl.5.1.2.2 | 4.0mm (min ) thickness of Test specimen |

| 2 | Tensile Strength | MPa | IS:3400 ( Part I) | Thick- 2.0 +.0.20mm |

| 3 | Elongation at Break | % | Table 1 Type -1 | Width 6.0 + 0.40mm Bench Mark-25..0mm (max) |

| 4 | Adhesion Strength (Metal to Rubber | KN/M | IS:3400 ( Part XIV) Cl.3.3 | Length -125mm Width-25mm Width-25mm 1 g (min) |

| 5 | Ash Content | % | IS:3400 (Part XXII) | 1 g (min) |

| 6 | Polymer Identification | Chemically | Cl. A-8.3.1 IS | |

| 7 | Percentage of Polymers | % | IS | 0.5 g (min) |

| 8 | Compression Set | % | IS: 3400 (Part X) Cl. 5.1 | Thick -12.5 + 0.50mm |

| 9 | Elastic Modulus | MPa | IRC 83 (Part II) | Dia-29 + 0.50mm 2 Nos from Finish |

| 10 | Shear Modulus | MPa | 1987, UIC 772 -2R | Product |

| 11 | Ultimate Compression Strength | MPa | and MORTH | One Specimen size of 100x200mm (Cutting Piece from Finish product.) |

| 12 | Stripping Strength (Adhesion Strength) | MPa | Two Specimen size of 100x 100mm (Cutting from Finish Product) | |

| 13 | 5MPa and 15 MPa Deflection Test | MPa | IRC 83 (Part II) 1987, and MORTH | 100% on finish Product. |