Discharge Hose

Ceramic Rubber Hose :

Good quality high wear resistat ceramic lined rubber hose, in th newly developed ceramic hose, ceramic tiles are used to eliminate a disadvantage in conventional ceramic hoses, it has higher abrasion resistance while maintaining flexibility. Ceramic hose has the circular disk shaped ceramic tip as compared with the conventional ball shaped ceramic tip and shows several times abrasion resistance.

1. Application Fields :Our products are widely used in steel plants, cement plants, power plants, coal mine, glassworks, etc.

2. Advantage :We have applied for a patent for our ceramic products. Also, they have been exported to many countries and areas.

Feature & Quality:

- Wear-resistant: Ceramic lining hose is 12 times more wear-resistant than stainless stell hose.

- Impact resistant: virtually impossible to destroy the ceramic segments.

- Flexible Minimum bend radius is roughly 12 times of the hose I.D.

- Corrosion -resistant: Compatible with most chemicals found in slurries.

- Widely of end- connection: suitable variety fittings and Flange.

- Long Length: Purchase and continuous length up to 65Ft.

- Widely hose diameter: 28 to 300mm in hose diameter.

Lined ceramic chips are made with cold pressing method.

Lining : EPDM rubber hose with lined ceramic (92% alumina) inside

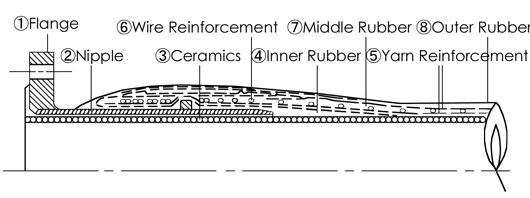

Reinforcement : For large size ceramic hose, a steel wire is usually embedded in helix structure on polyester fabric to reinforce the strength.

Cover : black NR/EPDM rubber

High resistance to abrasion,heat and corrosion

Longer service life

Having four end connection:plug-in connector,reinforced plug-in connector, flange connection and bayonet connection

The Flexible Hose with Ceramic Tiles.

SANDHYAFLEX are used to use the flexible hose with ceramic balls to reduce the internal costs.Our R & D experts were developed the ceramic tile has roughly five times longer useful life than flexible hose with ceramic balls.

How to Selection Ceramic Hose

The right selection means choosing a product suitable for technical requirement s of certain application or device along with assurance of safe and faultless performance Due to above mentioned reasons. We advise you contact us and help to choose the right ceramic hose.

The essential information for the right ceramic hose selection as follows:

- Medium : Substance conveyed.

- Internal diameter : 25-300mm.

- Pressure : maximal working pressure.

- Temperature : Both inside and outside temperature.

- Hose Ending : Type of fitting thread size , Type of Sealing.

- Way of assembling the hose fittings. Clip. Band. clamp.

- Length of the hose:Assembly the complete length along with fitting.

Technical Parameter:

| Working pressure | 10-30 bar |

| Rockwell hardness | 90 |

| Working temperature | -20ºC~120ºC |

| Curve degree | flexibility |

| Inner diameter | 30mm-300mm, custom-made |

| Max length | 15 m |

| Material | RUBBER |

| Color | Black |

Abrasive materials (coal powder, slurry, cinder etc.) conveyance in industries e.g. mining industry, dredging, steel industry, cement industry, power plant etc. requires flexible conveyance mediums at complex regions. Traditionally Rubber hoses are used for flexible requirements but are to be frequently replaced due to wear. The replacement frequency of the hose not only increases maintenance cost but also affects & delays production.

Our SANDHYAFLEX ceramic lined flexible rubber hoses are ideal for these situations offering extreme resistance to wear, vibrations, impact & thermal expansions. This hose can be easily connected to existing piping systems by means of flanges as end connection offering excellent flexibility support.

Features :

Shape : Cylindrical

Size : As per customer requirement

Colour : Black (Rubber) & White (Ceramic)

Weight : Lighter than steel

Properties : Impact & abrasion resistance, Anti-corrosive

Applications :

- Dredging

- Mining

- Cement

- Steel

- Power plants

Application Areas :

Ceramic hoses are widely used in steel mills. Cement plants, Powder plants. Waste Disposal Plants, Coal mines, Mining , Glass products. Sandblasting.

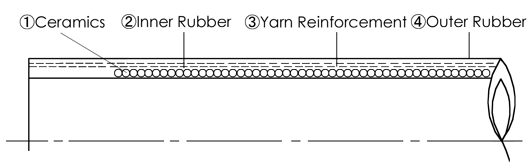

1. Lining

Built-in ceramic lining (92% alumina) EPDM rubber hose, high wear resistance, more efficient. in the newly developed ceramic hoses, the ceramic tip is used to eliminate the drawbacks of conventional ceramic hoses. It has a higher wear resistance, while maintaining flexibility

Application areas:

Ceramic hoses are widely used in steel mills, cement plants, power plants, waste disposal plants, coal mines, mining, glass products, sandblasting, concrete pump, dredging, desliming and other fields.

Ceramic lined flexible rubber hoses

ceramic-lined flexible hoses are ideal for use in highly aggressive services where conventional rubber hose, expansion joints, or bellows connections require frequent replacement. QMX hoses may also be used to isolate mechanical vibration or to connect non-stationary equipment.

Dry abrasion line of powder delivery

(Sand, grid, powdered coal, grain, cement and other fine powder) For both delivery and suction

Features :

Abrasion Resistance

Composite of aluminum ceramics and rubber with high elasticity and strength for inner material.

Excellent abrasion resistance against dry abrasion. Inner Rubber Layer

Inner rubber is complied by composite of ceramic balls (diameter ø3 to ø10) or Hex ceramic tiles and binder rubber with strong adhesion.

Ceramic lining is 12 times more wear-resistant than stainless steel

- Impact resistant - virtually impossible to destroy the ceramic segments

- Flexible - minimum bend radius is roughly 12 times the hose I.D.

- Corrosion-resistant - compatible with most chemicals found in slurries

- Wide variety of end-connections

- Purchase any continuous length up to 65 feet Straight Type (No Fittings)

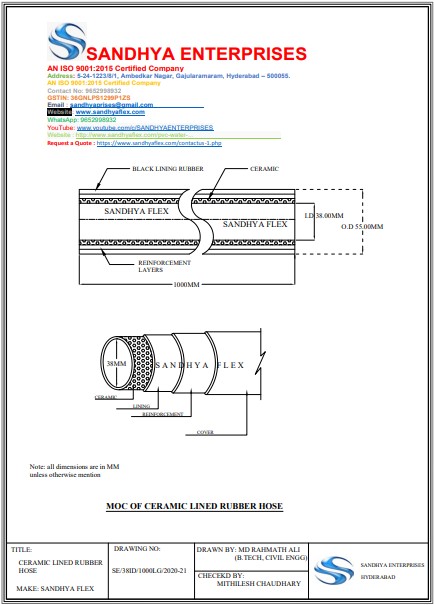

MOC

150mmID x 215mm OD x2040mm (LG) Both End MS Flange Rotating

| 150.00 | Sl.No. | Description | Thickness |

|---|---|---|---|

| 170.00 | 1 | Ceramic 10.0mm | 10.00 |

| 190.00 | 2 | Lining Double Rubber 5.0mm | 10.00 |

| 193.00 | 3 | 3 ply 240Z(27"+ 27"+ 27") | 0.50 |

| 197.40 | 4 | Middle Rubber 2.20mm | 2.20 |

| 5 | MS Helical Water10 SWG | 3.20 | |

| 202.40 | 6 | Middle Rubber 220mm | 2.50 |

| 204.40 | 7 | 2 ply 240Z (28"+ 28"} | 0.50 |

| 208.80 | 8 | Middle Rubber 2.2mm | 2.20 |

| 210.80 | 11 | 2 ply 240Z (29"+29") | 0.50 |

| 215.20 | 12 | Cover 2.2mm | 2.20 |

| 13 | Ratating MS Flange 1 Set | ||

| 14 | Slution CGS-18 | ||

| 15 | 3" Nylon tape |

Wall Thickness: 32.60

Weight: 33.096kgs

280mmID x 360mm OD x2.2Mtr (LG) Both End MS Flange (Rotaing)

| 280.00 | Sl.No. | Description | Thickness | Qty |

|---|---|---|---|---|

| 306.00 | 1 | 1 Ply One Side Ceramic Cloth 13.0mm Thick | 13.00 | 0.000 |

| 326.00 | 2 | Lining Double LAS 721 (4x2=8mm) | 10.00 | 27.410 |

| 330.00 | 3 | 4 ply 240Z(45"+45"+45"+45" | 0.50 | 10.516 |

| 335.00 | 4 | Middle Rubber 3.0mm | 2.50 | 8.615 |

| 5 | MS Helical Water 8SWG | 4.00 | 4.500 | |

| 341.00 | 6 | Middle Rubber 3.0mm | 3.00 | 8.770 |

| 344.00 | 7 | 3 ply 240Z (47"+47"+47"} | 0.50 | 8.240 |

| 350.00 | 8 | Middle Rubber 3.0mm | 3.00 | 9.133 |

| 9 | MS Helical Water 10 SWG | 3.20 | 3.500 | |

| 356.00 | 10 | Middle Rubber 3.0mm | 3.00 | 9.130 |

| 359.00 | 11 | 3 ply 240Z (49"+19"+49") | 0.50 | 8.588 |

| 362.00 | 12 | Cover | 3.00 | 9.290 |

| 13 | Ratating MS Flange 1 Set | |||

| 14 | Solution CGS-18 | 3.800 | ||

| 15 | 3" Nylon tape | 0.180 |

MOC :50mm ID x 85mmODx10.Mtr -04Nos

Ceramic Rubber Hose

50mmID x 85mm OD x10.0Mtr (LG)

| 50.00 | Sl.No. | Description | Thickness | Qty |

|---|---|---|---|---|

| 60.00 | 1 | 1 Ply One Side Ceramic Tiles 5.0mm Thick | 5.00 | 0.000 |

| 70.00 | 2 | Lining 5mm | 5.00 | 12.770 |

| 72.00 | 3 | 2 ply 240Z (10"+10") | 0.50 | 5.080 |

| 76.00 | 4 | Middle Rubber2.0mm | 2.00 | 5.815 |

| 5 | MS Helical Water 12 SWG | 2.60 | 14.000 | |

| 80.00 | 6 | Middle Rubber 2.0mm | 2.00 | 6.130 |

| 82.00 | 7 | 2 ply 240Z 11"+11"} | 0.50 | 5.600 |

| 86.00 | 8 | Cover 2.0mm | 2.00 | 6.600 |

| 13 | Ratating MS Flange 1 Set | |||

| 14 | Slution CGS-18 | 2.800 | ||

| 15 | 3" Nylon tape | 0.250 |

Wall Thickness: 35mm

Weight: 47.509kgs

50mmID x 85mm OD x10.0Mtr (LG)

| 50.00 | Sl.No. | Description | Thickness | Qty |

|---|---|---|---|---|

| 60.00 | 1 | 1 Ply One Side Ceramic Tiles 5.0mm Thick | 5.00 | 0.000 |

| 70.00 | 2 | Lining 5mm | 5.00 | 12.770 |

| 72.00 | 3 | 2 ply 240Z (10"+10") | 0.50 | 5.080 |

| 76.00 | 4 | Middle Rubber2.0mm | 2.00 | 5.815 |

| 5 | MS Helical Water 12 SWG | 2.60 | 14.000 | |

| 80.00 | 6 | Middle Rubber 2.0mm | 2.00 | 6.130 |

| 82.00 | 7 | 2 ply 240Z 11"+11"} | 0.50 | 5.600 |

| 86.00 | 8 | Cover 2.0mm | 2.00 | 6.600 |

| 13 | Ratating MS Flange 1 Set | |||

| 14 | Slution CGS-18 | 2.800 | ||

| 15 | 3" Nylon tape | 0.250 |

Wall Thickness: 35mm

Weight: 48.509kgs

62mmID x 108mm OD x 710mm (LG) Both End MS Flange

| 62.00 | Sl.No. | Description | Thickness | Qty |

|---|---|---|---|---|

| 72.00 | 1 | Ceramic 5.0mm | 5.00 | 0.000 |

| 92.00 | 2 | Lining 5mmx 2 Layer | 10.00 | 2.300 |

| 94.00 | 3 | 2 ply 240Z (13"+13") | 0.50 | 0.470 |

| 98.00 | 4 | Middle Rubber 2.0mm | 2.00 | 0.536 |

| 5 | MS Helical Water 12 SWG | 2.60 | 0.600 | |

| 102.00 | 6 | Middle Rubber 2.0mm | 2.00 | 0.560 |

| 104.00 | 7 | 2 ply 240Z 14"+14"} | 0.50 | 0.505 |

| 108.00 | 8 | Cover 2.0mm | 2.00 | 0.800 |

| 13 | MS Flange 1 Set | |||

| 14 | Slution CGS-18 | 2.000 | ||

| 15 | 3" Nylon tape | 0.180 |

Wall Thickness: 36mm

Weight: 6.0kg

62mmID x 108mm OD x 915mm (LG) Both End MS Flange

| 62.00 | Sl.No. | Description | Thickness | Qty |

|---|---|---|---|---|

| 72.00 | 1 | Ceramic 5.0mm | 5.00 | 0.000 |

| 92.00 | 2 | Lining 5mmx 2 Layer | 10.00 | 2.950 |

| 94.00 | 3 | 2 ply 240Z (13"+13") | 0.50 | 0.605 |

| 98.00 | 4 | Middle Rubber 2.0mm | 2.00 | 0.690 |

| 5 | MS Helical Water 12 SWG | 2.60 | 0.700 | |

| 102.00 | 6 | Middle Rubber 2.0mm | 2.00 | 0.720 |

| 104.00 | 7 | 2 ply 240Z 14"+14"} | 0.50 | 0.650 |

| 108.00 | 8 | Cover 2.0mm | 2.00 | 0.765 |

| 13 | MS Flange 1 Set | |||

| 14 | Slution CGS-18 | 2.000 | ||

| 15 | 3" Nylon tape | 0.180 |

Wall Thickness: 36mm

Weight: 6.5kg

62mmID x 108mm OD x 1000mm (LG) Both End MS Flange

| 62.00 | Sl.No. | Description | Thickness | Qty |

|---|---|---|---|---|

| 72.00 | 1 | Ceramic 5.0mm | 5.00 | 0.000 |

| 92.00 | 2 | Lining 5mmx 2 Layer | 10.00 | 3.221 |

| 94.00 | 3 | 2 ply 240Z (13"+13") | 0.50 | 0.660 |

| 98.00 | 4 | Middle Rubber 2.0mm | 2.00 | 0.755 |

| 5 | MS Helical Water 12 SWG | 2.60 | 0.800 | |

| 102.00 | 6 | Middle Rubber 2.0mm | 2.00 | 0.755 |

| 104.00 | 7 | 2 ply 240Z 14"+14"} | 0.50 | 0.715 |

| 108.00 | 8 | Cover 2.0mm | 2.00 | 0.835 |

| 13 | MS Flange 1 Set | |||

| 14 | Slution CGS-18 | 2.000 | ||

| 15 | 3" Nylon tape | 0.180 |

Wall Thickness: 36mm

Weight: 7.0kg

MOC of 4” ID x 1.0Mtr (LG)

| 101.60 | Sl.No. | Description | Thickness |

|---|---|---|---|

| 109.60 | 1 | Lining | 4.00 |

| 112.80 | 2 | 2 Ply 18 OZ | 0.80 |

| 0.00 | 3 | MS Wire 12 SWG | 2.60 |

| 114.80 | 4 | Middle | 0.80 |

| 119.40; | 5 | Cover | 1.50 |

Wall Thickness 9.0 to 10.mm

MOC of 12” ID x1.0Mtr

| 300.00 | Sl.No. | Description | Thickness |

|---|---|---|---|

| 316.00 | 1 | Lining | 8.00 |

| 320.80 | 2 | 3 Ply 240Z | 0.80 |

| 323.80 | 4 | Middle | 1.50 |

| 0.00 | 3 | MS Wire 10 SWG | 3.20 |

| 326.80; | 4 | Middle | 1.50 |

| 330.00 | 5 | 2 Ply 240Z | 0.80 |

| 336.00 | 4 | Middle | 1.50 |

| 0.00 | 6 | MS Wire 10 SWG | 3.20 |

| 339.00 | 7 | Middle | 1.50 |

| 342.20 | 8 | 2 Ply 240Z | 0.80 |

| 345.20 | 9 | Cover | 1.50 |

Wall Thickness 22 to 23mm